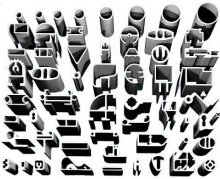

Dalle

Tôle

Barre ronde

Tube / Extrusion / Profil

5251

BS 3L81 / AlMg2Mn0.3 / 5251 / H26 / H36

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,00 - 0,15 |

| Manganese (Mn) | 0,10 - 0,50 |

| Magnesium (Mg) | 1,70 - 2,40 |

| Copper (Cu) | 0,00 - 0,15 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,15 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,68 g/cm³ |

| Melting Point | 605 °C |

| Thermal Expansion | 23.6 x 10^-6 /K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | %38 IACS |

| Mechanical Properties | Value |

| Proof Strength | 200 |

| Yield Strength | 250 |

| Elongation A50 mm | %8 |

| Modulus of Elasticity | 70 GPa |

Aluminium alloy 5251 is a medium strength alloy possessing good ductility and therefore good formability. Alloy 5251 is known for work hardening rapidly and is readily weldable. It also possesses high corrosion resistance particularly in marine environments.

ALLOY DESIGNATIONS

BS 3L81, 5251 has s imilarities to the following standard designations and specifications ;

Alloy 5251, UNS A95251, ASTM B209

ISO AlMg2Mn0.3, 3.3525

BS N4

TEMPER TYPES

5251 is supplied in a wide range of tempers:

- O - Soft

- H111 - Annealed and slightly strain-hardened (less than H11) during subsequent operations such as stretching or levelling.

- H16 - Strain-hardened - 3/4 hard.

- H26 - Strain-hardened and partially annealed - 3/4 hard.

- H36 - Strain-hardened and stabilized - 3/4 hard.

SUPPLIED FORMS

5251 is supplied in sheet

- Sheet

DELIVERY:

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 0,2 up to & incl. 0,5 | 170 | 270 | %3 |

| Over 0,5 up to & incl. 1,2 | 170 | 270 | %4 |

| Over 1,5 up to & incl. 3,0 | 170 | 270 | %5 |

| Over 3,0 up to & incl. 4,0 | 170 | 270 | %7 |

Calculateur de Poids

Calculateur de Poids