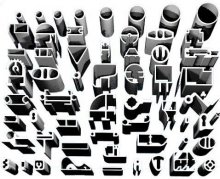

Plates

Sheets

Rod / Round Bar / Flat Bar

Tube / Extrusions / Profile

2014 / 2014A

BS L168 / AlCu4SiMg / 2014 / 2014A / T6

| Chemical Properties | % Value |

| Silicon (Si) | 0,50 - 0,90 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,40 - 1,20 |

| Magnesium (Mg) | 0,20 - 0,80 |

| Copper (Cu) | 3,90 - 5,00 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,25 |

| Nickel (Ni) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.80 g/cm³ |

| Melting Point | 505 °C |

| Thermal Expansion | 22.8 x 10^-6 /K |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 160 W/m.K |

| Electrical Resistivity | %40 IACS |

| Mechanical Properties | Value |

| Proof Strength | 430 MPa |

| Yield Strength | 500 MPa |

| Elongation A50 mm | %9 |

| Modulus of Elasticity | 72 GPa |

High strength structural components for aircraft , military vehicles and bridges, weapons manufacture, structural applications.

ALLOY DESIGNATIONS

Aluminium alloy 2014 / 2014A is covered by Standard BS EN 2100 and has similarities to the following standard designations and specifications:

2014 / 2014A, AMS 4029, ISO AlCu4SiMg, 3.1255

DIN AlCuSiMn, UNS A92014, BS L93, DTD 5010

TEMPER TYPES

The most common tempers for 2014 / 2014A aluminium are:

- O - Soft

- T3 - Solution heat treated, cold worked and naturally aged

- T4 - Solution heat treated and naturaly aged to a substantially stable condition

- T6 - Solution heat treated and artificially aged

- T651 - Solution heat treated, stress relieved by stretching then artificially aged

SUPPLIED FORMS

AMS 4029 aluminium is supplied in Plate.

- Plate

DELIVERY:

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 25 up to & incl. 75 | 415 MPa | 460 MPa | %7 |

| Over 150 up to & incl. 200 | 350 MPa | 430 MPa | %6 |

| Over 200 up to & incl. 250 | 320 MPa | 420 MPa | %5 |

Weight Calculator

Weight Calculator