2030

EN AW / AlCuMgPb / 2030 / T4/T4510/T4511

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,80 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,20 - 1,00 |

| Magnesium (Mg) | 0,50 - 1,00 |

| Copper (Cu) | 3,50 - 4,50 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,50 |

| Lead (Pb) | 0,80 - 1,00 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.82 g/cm³ |

| Melting Point | 520 °C |

| Thermal Expansion | 23 x 10^-6 /K |

| Modulus of Elasticity | 73,6 GPa |

| Thermal Conductivity | 190 W/m.K |

| Electrical Resistivity | %40 IACS |

| Mechanical Properties | Value |

| Proof Strength | 240 MPa |

| Yield Strength | 370 MPa |

| Elongation A50 mm | %7 |

| Modulus of Elasticity | 73,6 GPa |

A medium strength alloy with, dependent upon temper, minimum Proof Stress up to 250 Mpa and minimum Tensile Strength up to 370 MPa

ALLOY DESIGNATIONS

Aluminium alloy 2030 has similarities to the following standard designations and specifications:

AU4Pb, Alloy 2030, UNS A92030, ASTM B211

DIN AlCuMgPb, 3.1645, ISO AlCuPbMg,

TEMPER TYPES

2030 is supplied in a wide range of tempers:

T351 is intended to provide material with low residual stresses and thus minimal distortion during machining, but does not provide optimal corrosion resistance.

- O - Soft

- T3 - Solution heat treated, cold worked and naturally aged

- T4 - Solution heat treated and naturaly aged to a substantially stable condition

- T351 - Solution heat treated then stress relieved by stretching. Equivalent to T4 condition.

- T4510 - Solution heat treated and stressrelieved by stretching - Equivalent to T4 condition

- T4511 - Solution heat treated and stressrelieved by stretching - Equivalent to T4 condition

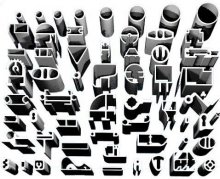

SUPPLIED FORMS

Alloy 2030 is supplied in bar, round bar, tube, profile and extrusions.

- Bar / Round Bar

- Tube / Profile / Extrusions

Weight Calculator

Weight Calculator