5754

EN AW / AlMg3 / 5754 / O / H111

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,25 |

| Chromium (Cr) | 0,05 - 0,20 |

| Manganese (Mn) | 0,50 - 1,00 |

| Magnesium (Mg) | 4,70 - 5,50 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,66 g/cm³ |

| Melting Point | 568 °C |

| Thermal Expansion | 23.9 x 10^-6 /K |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 120 W/m.K |

| Electrical Resistivity | %29 IACS |

| Mechanical Properties | Value |

| Proof Strength | 250 MPa |

| Yield Strength | 330 MPa |

| Elongation A50 mm | %13 |

| Modulus of Elasticity | 69 GPa |

Aluminium alloy 5754 has excellent corrosion resistance especially to seawater and industrially polluted atmospheres.

ALLOY DESIGNATIONS

Aluminium alloy EN AW 5754 has similarities to the following standard designations and specifications ;

Alloy 5754 UNS A95754, ASTM B209

DIN AlMg

TEMPER TYPES

5754 is supplied in a wide range of tempers:

- O - Soft

- H111 - Annealed and slightly strain-hardened (less than H11) during subsequent operations such as stretching or levelling.

- H112 - Applies to alloys that acquire some temper from shaping processes which do not have special control over the amount of strain-hardening or thermal treatment, but for which there are mechanical property limits.

- H28 - Strain-hardened and partially annealed - 4/4 hard (fully hardened).

- H32 - Work hardened by rolling then stabilised by low-temperature heat treatment to quarter hard

- H34 - Strain-hardened and stabilized - 1/2 hard.

- H36 - Strain-hardened and stabilized - 3/4 hard.

- H38 - Strain-hardened and stabilized - 4/4 hard (fully hardened).

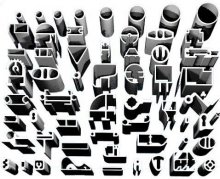

SUPPLIED FORMS

5754 is supplied in plate, sheet, bar and extrusions.

- Plate

- Sheet

- Round Bar / Bar

- Tube / Extrusions

DELIVERY:

Weight Calculator

Weight Calculator