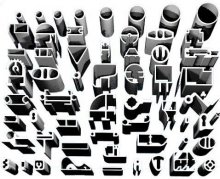

Plates

Sheets

Rod / Round Bar / Flat Bar

Tube / Extrusions / Profile

6082

BS L113 / AlSi1MgMn / 6082 / T6

| Chemical Properties | % Value |

| Silicon (Si) | 0,70 - 1,30 |

| Chromium (Cr) | 0,00 - 0,25 |

| Manganese (Mn) | 0,40 - 1,00 |

| Magnesium (Mg) | 0,60 - 1,20 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.71 g/cm³ |

| Melting Point | 575 °C |

| Thermal Expansion | 23.1 x 10^-6 /K |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 170 W/m.K |

| Electrical Resistivity | %44 IACS |

| Mechanical Properties | Value |

| Proof Strength | 270 MPa |

| Yield Strength | 330 |

| Elongation A50 mm | %16 |

| Modulus of Elasticity | 71 GPa |

Aluminium alloy 6082 is a medium strength alloy with excellent corrosion resistance. It has the highest strength of the 6000 series alloys. Alloy 6082 is known as a structural alloy. In plate form, 6082 is the alloy most commonly used for machining. As a relatively new alloy, the higher strength of 6082 has seen it replace 6061 in many applications.

ALLOY DESIGNATIONS

Aluminium alloy 6082, BS L113 also corresponds to the following standard designations and specifications but may not be a direct equivalent:

Alloy 6082

HS30

DIN 3.2315

EN AW-6082

ISO AlSi1MgMn

UNS A96082

TEMPER TYPES

BS L113, 6082 is supplied in a wide range of tempers:

- O - Soft

- T6 - Solution heat treated and artificially aged

- T4 - Solution heat treated and naturaly aged to a substantially stable condition

- T651 - Solution heat treated, stress relieved by stretching then artificially aged

- T6511 - Solution heat-treated, stress-relieved by controlled stretching and minor straightening is allowed after stretching to comply with standard tolerances then artificially aged.

SUPPLIED FORMS

6082 is supplied in plate, bar, round bar, tube, extrusion and sheet.

- Plate

- Sheet

- Round Bar / Bar

- Tube / Extrusion

DELIVERY:

Weight Calculator

Weight Calculator