2011

EN AW / AlCu6BiPb / 2011 / T3

| Chemical Properties | % Value |

| Silicon (Si) | 0,40 Max |

| Copper (Cu) | 3,90 - 5,00 |

| Lead (Pb) | 0,20 - 0,60 |

| Iron (Fe) | 0,70 Max |

| Zinc (Zn) | 0,00 - 0,20 |

| Nickel (Ni) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.82 g/cm³ |

| Melting Point | 540 °C |

| Thermal Expansion | 22.9 x 10^-6 /K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | %39 IACS |

| Mechanical Properties | Value |

| Proof Strength | 290 MPa |

| Yield Strength | 340 MPa |

| Shear Strength | 220 MPa |

Aluminium alloy 2011 is a high mechanical strength alloy that machines exceptionally well. Often called a Free Machining Alloy or ‘FMA’ it is well suited to use in automatic lathes.

ALLOY DESIGNATIONS

Aluminium alloy EN AW 2011 is covered by Standard BS EN 2100 and has similarities to the following standard designations and specifications:

Alloy 2011 UNS A92011, ASTM B209

DIN AlCu6BiPb, 3.1655

TEMPER TYPES

The most common tempers for 2011 aluminium are:

- O - Soft

- T3 - Solution heat treated, cold worked and naturally aged

- T4 - Solution heat treated and naturaly aged to a substantially stable condition.

- T8 - Solution heat-treated, cold worked and then artificially aged.

- T451 - Solution heat-treated, stress-relieved by controlled stretching and then artificially overaged (between T73 and T76). The products receive no further straightening after stretching.

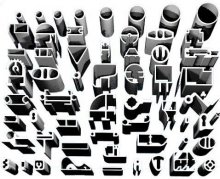

SUPPLIED FORMS

2011 aluminium is supplied in round bar.

- Round Bar

DELIVERY:

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 3,17 up to & incl. 38,1 | 260 MPa | 310 MPa | %10 |

| Over 38,13 up to & incl. 50,8 | 235 MPa | 295 MPa | %10 |

| Over 50,83 up to & incl. 82,5 | 205 MPa | 290 MPa | %14 |

Weight Calculator

Weight Calculator