2007

EN AW / AlCu4PbMgMn / 2007 / T3 / T351

| Chemical Properties | % Value |

| Silicon (Si) | 0,40 Max |

| Copper (Cu) | 3,90 - 5,00 |

| Lead (Pb) | 0,20 - 0,60 |

| Iron (Fe) | 0,70 Max |

| Zinc (Zn) | 0,00 - 0,20 |

| Nickel (Ni) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.82 g/cm³ |

| Melting Point | 510 °C |

| Thermal Expansion | 23 x 10^-6 /K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | %47 IACS |

| Mechanical Properties | Value |

| Proof Strength | 250 MPa |

| Yield Strength | 390 MPa |

| Shear Strength | 230 MPa |

| Elongation A50 mm | %6,8 |

| Modulus of Elasticity | 71 GPa |

A copper alloy that typically contains between 4.0 and 5.0 % copper, and it is suitable for producing machine parts, bolts and rivets. It looks very much like 2011, it is a bit more harder.

ALLOY DESIGNATIONS

Aluminium alloy EN AW 2007 is covered by Standard BS EN 2100 and has similarities to the following standard designations and specifications:

Alloy 2007, UNS A92007, ASTM B209

DIN AlCu4PbMgMn, 3.1645

TEMPER TYPES

The most common tempers for 2011 aluminium are:

- O - Soft

- T3 - Solution heat treated, cold worked and naturally aged

- T4 - Solution heat treated and naturaly aged to a substantially stable condition.

- T8 - Solution heat-treated, cold worked and then artificially aged.

- T451 - Solution heat-treated, stress-relieved by controlled stretching and then artificially overaged (between T73 and T76). The products receive no further straightening after stretching.

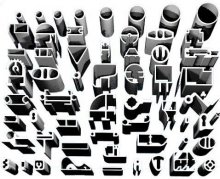

SUPPLIED FORMS

2007 aluminium is supplied in round bar/bar, tube and sheet.

- Round Bar

- Bar

- Sheet

Weight Calculator

Weight Calculator