لوحات/ طباقات

صاج

قضيب

أنابيب

5083

ASTM B221 / AlMg4.5Mn0.7 / 5083 / H111

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,05 - 0,25 |

| Magnesium (Mg) | 4,00 - 4,90 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Manganese (Mn) | 0,40 - 1,00 |

| Physical Properties | Value |

| Density | 2.66 g/cm³ |

| Melting Point | 574 °C |

| Thermal Expansion | 23.9 µm/m.°C |

| Modulus of Elasticity | 68 GPa |

| Thermal Conductivity | 121 W/m.K |

| Electrical Resistivity | 29% IACS |

| Mechanical Properties | Value |

| Proof Strength | 150 MPa |

| Yield Strength | 310 MPa |

| Shear Strength | 180 MPa |

| Elongation A50 mm | 13% |

| Hardness | 75 HB |

سبائك الألمنيوم 5083 H111 مشهورة بمقاومتها الممتازة للتآكل، وقوتها العالية، وسهولة تشكيلها. تركيبها من المغنيسيوم والمنغنيز والكروم يجعلها متينة بشكل خاص في البيئات البحرية والظروف الكيميائية القاسية والعوامل البيئية القاسية. يشير المعالجة H111 إلى أن السبيكة خضعت للمعالجة الحرارية وتشكيل خفيف لتحقيق الاستقرار، مما يوفر توازنًا جيدًا بين القوة وسهولة التشكيل.

يشير المعالجة H111 إلى أن السبيكة خضعت للمعالجة الحرارية وتشكيل خفيف لتحقيق الاستقرار، مما يوفر توازنًا جيدًا بين القوة وسهولة التشكيل.

يتم استخدام هذه السبائك على نطاق واسع في بناء السفن، وخزانات التخزين، والأوعية الضغطية، وحاويات نقل المواد الكيميائية، والهياكل البحرية حيث تعتبر المتانة أمرًا بالغ الأهمية. 5083 H111 متوافقة مع الأكسدة الأنودية، التي تشكل طبقة واقية على السطح لتعزيز مقاومة التآكل وتوفير مظهر جمالي جذاب. بالإضافة إلى ذلك، توفر السبيكة قابلية ممتازة للّحام باستخدام طرق TIG وMIG، مما يجعلها مثالية للهياكل الملحومة.

فيما يتعلق بالانحناء والتشكيل، فإن سبيكة الألمنيوم 5083 H111 تؤدي أداءً ممتازًا. انخفاض خطر التشقق أثناء عمليات التشكيل المعقدة يجعلها مناسبة للتصاميم التفصيلية والتطبيقات الدقيقة. مع مقاومة عالية للإجهاد واستقرار ميكانيكي، تتحمل السبيكة الأحمال الديناميكية والبيئات المعرضة للاهتزاز، مما يجعلها موثوقة للاستخدام في ظروف صعبة.

تشمل مزايا هذه السبائك مقاومة ممتازة للتآكل، وسهولة التشكيل، وسهولة اللحام، ووزن خفيف. أما العيوب فتشمل الأداء المحدود في درجات الحرارة العالية جدًا أو الأحمال المفرطة. تجعل هذه الخصائص 5083 H111 خيارًا ممتازًا للمشاريع التي تعطي الأولوية للمتانة والبناء خفيف الوزن ومقاومة التآكل.

الأشرطة المستديرة/المسطحة والبكرات والأسلاك والأنابيب حسب: 5083 H111, ASTM B221, UNS A95083, ASTM B928, WNR 3.3547, AMS QQ-A-200/4, ISO AlMg4.5Mn0.7, DIN AlMg4.5Mn

الألواح والصفائح حسب: 5083 H111, ASTM B209, UNS A95083, WNR 3.3547, AMS QQ-A-250/6, DIN AlMg4.5Mn, ISO AlMg4.5Mn0.7

عوامل الاختيار لـ 5083 H111

- القوة: جيدة جدًا

- سهولة التشغيل الآلي: ضعيفة

- قابلية اللحام: جيدة

- قابلية التشكيل: متوسطة

- مقاومة التآكل: جيدة جدًا

- المعالجة الحرارية: لا

بعض التطبيقات المعروفة لـ 5083 H111

في داخل السفن،

في خزانات الوقود،

ويُستخدم أيضًا في عربات السكك الحديدية.

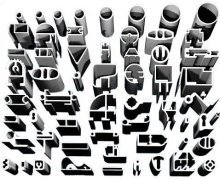

- لوح

- صفحة

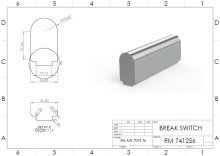

- قضيب / شريط مستدير / شريط مسطح

- أنبوب/بروفيل

حساب الوزن

حساب الوزن