Platos

Hojas

Barras Circulares

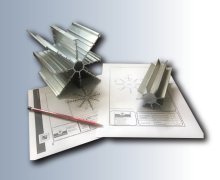

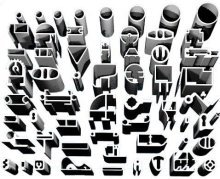

Tubos / Extrusion / Perfil

5456

AMS QQ-A-200/7 / AlMg5Mn1 / 5456 / H111

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,25 |

| Chromium (Cr) | 0,05 - 0,20 |

| Manganese (Mn) | 0,50 - 1,00 |

| Magnesium (Mg) | 4,70 - 5,50 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.66 g/cm³ |

| Melting Point | 568 °C |

| Thermal Expansion | 23.9 µm/m.°C |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 116 W/m.K |

| Electrical Resistivity | 29 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 230 MPa |

| Yield Strength | 320 MPa |

| Shear Strength | 195 MPa |

| Elongation A50 mm | 18% |

| Hardness | 87 HB |

The 5456 H111 aluminum alloy is known for its excellent corrosion resistance and outstanding durability, making it ideal for use in harsh environmental conditions. It is widely used in maritime, offshore, and other demanding applications. The 5456 H111 stands out due to its high vibration resistance, which makes it suitable for dynamic environments such as automotive, aerospace, and defense industries, where reliable performance in vibration-prone settings is essential.

This alloy is also suitable for anodizing, which enhances its surface aesthetically and functionally, providing an additional layer of protection against corrosion. Anodizing makes the alloy more resistant to external factors, thereby increasing its longevity. Additionally, 5456 H111 is highly weldable, allowing for easy welding with the proper techniques, which is a significant advantage in industrial production processes.

In terms of bending properties, 5456 H111 excels. Its high machinability allows it to be easily shaped and formed into the desired forms without difficulty. Furthermore, due to its corrosion resistance, the alloy can withstand harsh environments, such as seawater, for extended periods. This feature makes it especially popular in the maritime industry.

The advantages of the 5456 H111 alloy include its durability, corrosion resistance, anodizing compatibility, and weldability. However, it does have some drawbacks, such as a potential loss of hardness at low temperatures and limited formability in certain conditions. Nevertheless, 5456 H111 is an ideal choice for high-performance and reliability in industrial application

Sheets and plates per; 5456 H111, ISO AlMg5Mn1, ASTM B928, ASTM B209, AMS QQ-A-250/9, UNS A95456, MIL-A-19842C

Cold Drawn Tubes per; 5456 H111, ISO AlMg5Mn1, ASTM B210, UNS A95456, MIL-P-25995

Extruded Round/Flat Bar and Tubes per; 5456 H111, ISO AlMg5Mn1, ASTM B221, UNS A95456, MIL-A-21170A, AMS QQ-A-200/7

Choosing Factors for 5456 H111

- Strength: Moderate

- Machining: Weak

- Weldability: Very good

- Formability: Poor

- Corrosion Resistance: Excellent

- Heat Treating: None

Some Well-Known Applications for 5456 H111

In high-strength welded structures,

In overhead cranes,

It is also used in automotive industry.

SUPPLIED FORMS

- Sheet

- Round/Flat Bar

- Tube/Profile

- Plate

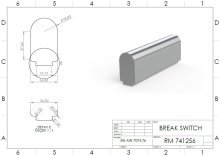

Calculador de Peso

Calculador de Peso