5754

CR 1.1.0.18 / AlMg3 / 5754 / H111

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,25 |

| Chromium (Cr) | 0,05 - 0,20 |

| Manganese (Mn) | 0,00 - 0,50 |

| Magnesium (Mg) | 2,60 - 3,60 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,67 g/cm³ |

| Melting Point | 598 °C |

| Thermal Expansion | 23.9 µm/m.°C |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 120 W/m.K |

| Electrical Resistivity | 33% IACS |

| Mechanical Properties | Value |

| Proof Strength | 90 MPa |

| Yield Strength | 210 MPa |

| Shear Strength | 130 MPa |

| Elongation A50 mm | %13 |

| Hardness | 52 HB |

تُعرف سبيكة الألمنيوم 5754 H111 بمقاومتها الممتازة للتآكل، وقابليتها الجيدة للتشغيل، وقوتها الميكانيكية المتوسطة. يمثل معيار H111 حالة من السبيكة التي تمت معالجتها وتقويتها بشكل خفيف، مما يمنحها مرونة ومتانة كافية. تجعل هذه الخصائص سبيكة 5754 H111 مثالية للاستخدام في البيئات الصعبة مثل البحرية، وصناعة السيارات، والهياكل الخارجية، والتطبيقات الصناعية. بالإضافة إلى ذلك، فإن ألمنيوم 5754 H111 مناسب لعملية الأنودة، التي تعمل على تحسين مظهر السطح وزيادة مقاومته للتآكل، مما يضمن أداءً طويل الأمد في الهواء الطلق.

من حيث قابلية اللحام، يمكن لحام سبيكة الألمنيوم 5754 H111 بنجاح. تساعد صلابتُها المتوسطة على تسهيل عملية اللحام وضمان وصلات قوية وموثوقة. ومع ذلك، فإن استخدام تقنيات المعالجة الحرارية المناسبة ضروري للحصول على أفضل النتائج. أما بالنسبة للانحناء، فإن ألمنيوم 5754 H111 يتمتع بدرجة عالية من المرونة، مما يجعله سهل التشكيل وقابلاً للانحناء، وهو ما يوفر مرونة كبيرة في التطبيقات المختلفة.

تتميز سبيكة 5754 H111 بمقاومة ممتازة للتآكل، خاصة في البيئات القاسية مثل مياه البحر، مما يجعلها مثالية للتطبيقات البحرية، وبناء السفن، والهياكل الخارجية. بالإضافة إلى ذلك، يمكن استخدام سبيكة الألمنيوم 5754 H111 في البيئات ذات الاهتزاز العالي، مما يمنحها ميزة في الصناعات مثل السيارات، والفضاء، والدفاع. تعمل متانتها العالية وأداءها طويل الأمد على تعزيز موثوقيتها في التطبيقات الديناميكية.

تشمل مزايا سبيكة الألمنيوم 5754 H111 مقاومتها العالية للتآكل، وقابليتها للأنودة، وقابليتها الممتازة للحام، وسهولة الانحناء. ومع ذلك، قد تكون قوتها الميكانيكية أقل مقارنةً بالسبائك الأكثر صلابة، مما قد يحد من استخدامها في التطبيقات الشاقة. كما قد تكون قابلية تشغيلها ميكانيكياً أقل مقارنةً بالسبائك الأكثر مرونة. على الرغم من هذه التحديات، تظل 5754 H111 خيارًا ممتازًا للظروف البيئية الصعبة والتطبيقات الصناعية.

الصفائح والألواح حسب المعايير: 5754 H111, ASTM B209, UNS A95754, WNR 3.3535, UNI AlMg3.5, UNE L-3390, AFNOR A-G3M, CR 1.1.0.18

القضبان المستديرة/المسطحة والأنابيب المبثوقة حسب المعايير: 5754 H111, ASTM B221, UNS A95754, WNR 3.3535, UNI AlMg3.5, UNE L-3390, AFNOR A-G3M, CR 1.1.0.18

عوامل اختيار 5754 H111

- القوة: جيدة

- التشغيل الميكانيكي: ضعيف

- قابلية اللحام: ممتازة

- قابلية التشكيل: متوسطة

- مقاومة التآكل: جيدة

- المعالجة الحرارية: لا يوجد

بعض التطبيقات المشهورة لـ 5754 H111

في صناعة الغلايات،

كصفائح مضلعة (Tread Plates)،

في الهياكل الكيميائية الملحومة.

- لوح

- صفيحة

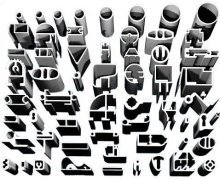

- قضيب / قضيب مستدير / قضيب مسطح

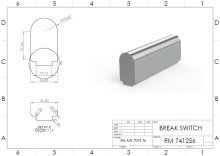

- أنبوب/بروفيل

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 0.2 up to & incl. 0.5 | ≥ 80 MPa | 190–240 MPa | ≥ 12 |

| Over 0.5 up to & incl. 1.5 | ≥ 80 MPa | 190–240 MPa | ≥ 14 |

| Over 1.5 up to & incl. 3.0 mm | ≥ 80 MPa | 190–240 MPa | ≥ 14 |

| Over 3.0 up to & incl. 12.5 mm | ≥ 80 MPa | 190–240 MPa | ≥ 18 |

| Over 12.5 up to & incl. 100 mm | ≥ 80 MPa | 190–240 MPa | ≥ 19 |

حساب الوزن

حساب الوزن