لوحات/ طباقات

صاج

قضيب

أنابيب

6082

ASTM B211 / AlMgSi1 / AlSi1MgMn / 6082 / T6

| Chemical Properties | % Value |

| Silicon (Si) | 0,70 - 1,30 |

| Chromium (Cr) | 0,00 - 0,25 |

| Manganese (Mn) | 0,40 - 1,00 |

| Magnesium (Mg) | 0,60 - 1,20 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.71 g/cm³ |

| Melting Point | 575 °C |

| Thermal Expansion | 23.1 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 160 W/m.K |

| Electrical Resistivity | %42 IACS |

| Mechanical Properties | Value |

| Proof Strength | 270 MPa |

| Yield Strength | 330 MPa |

| Shear Strength | 220 MPa |

| Elongation A50 mm | 10% |

| Hardness | 93 HB |

The 6082 T6 aluminum alloy is known for its high mechanical strength, excellent corrosion resistance, and good machinability. It is widely used in industries such as automotive, aerospace, construction, and transportation, particularly for structural applications that require high tensile strength and durability. The T6 temper is achieved through heat treatment, which enhances the alloy's hardness and strength, making it ideal for heavy-load-bearing applications. Additionally, 6082 T6 is suitable for anodizing, which provides both aesthetic enhancement and increased corrosion resistance.

In terms of weldability, 6082 T6 performs well, but due to its high hardness and strength, proper welding techniques are required. The alloy also has excellent bending properties. With the appropriate machinery, 6082 T6 can be easily shaped into the desired forms, although bending may require more attention due to the hardness of the T6 temper.

The corrosion resistance of 6082 T6 is exceptional, particularly against seawater and other harsh environmental conditions. This makes it a preferred material for industries such as maritime, construction, and outdoor structures. Moreover, 6082 T6 can also be used in high-vibration environments, making it suitable for dynamic industries like automotive and aerospace. Its durability and long-lasting performance ensure it meets the demands of these industries.

The advantages of 6082 T6 include high mechanical strength, corrosion resistance, anodizing compatibility, weldability, and excellent bending properties. However, its performance may be limited in highly abrasive environments, and it may experience a loss of hardness at low temperatures. Despite these drawbacks, 6082 T6 is an excellent choice for many industrial applications that require durability, high performance, and reliability.

As Sheet/Plate; 6082 T6, ISO AlSi1MgMn, ASTM B209, UNS A96082, WNR 3.2315, BS L 113, BS HS 30

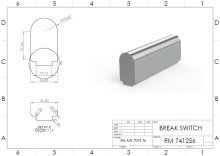

As Extruded Round/Flat Bar; 6082 T6, ISO AlSi1MgMn, ASTM B221, UNS A96082, WNR 3.2315, BS L 111, BS HE 30, EN 2326

As Cold Drawn Round/Flar Bar, Tube; 6082 T6, ISO AlSi1MgMn, ASTM B211, UNS A96082, WNR 3.2315, BS L 114, BS HT 30, EN 2636

Choosing Factors for 6082 T6

- Strength: Very good

- Machining: Fair

- Weldability: Good

- Formability: Okay

- Corrosion Resistance: Excellent

- Heat Treating: Yes

Some Well-Known Applications for 6082 T6

In ore skips, bridges,

In cranes and transportation industry,

It has a wide variety of uses, including in sea boats and wagons.

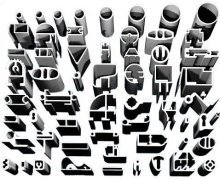

- Plate/ Sheet

- Rod / Round Bar / Flat Bar

- Tube/Profile

حساب الوزن

حساب الوزن