Листы/Плиты

Лист

Бар/Листовая Сталь

Трубы/Профили

2030

ASTM B221 / AlCu4PbMg / 2030 / T4

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,80 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,20 - 1,00 |

| Magnesium (Mg) | 0,50 - 1,30 |

| Copper (Cu) | 3,30 - 4,50 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,50 |

| Lead (Pb) | 0,80 - 1,50 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.81 g/cm³ |

| Melting Point | 520 °C |

| Thermal Expansion | 23.0 µm/m.°C |

| Modulus of Elasticity | 73 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | %34 IACS |

| Mechanical Properties | Value |

| Proof Strength | 240 MPa |

| Yield Strength | 380 MPa |

| Shear Strength | 220 MPa |

| Elongation A50 mm | 8% |

| Hardness | 112 HB |

2030 T4 aluminum alloy is distinguished by its excellent machinability, good mechanical strength, and moderate corrosion resistance. Its copper-heavy composition enhances its strength properties, while the T4 temper indicates that the alloy has undergone solution heat treatment and stabilized through natural aging. These features make it a durable and reliable material for demanding applications.

This alloy is particularly suitable for components used in the automotive, aerospace, defense, and industrial sectors. It is commonly used for chassis components, engine parts, and machine elements that require precision machining and high strength. 2030 T4 is compatible with anodizing, forming a protective oxide layer that enhances its corrosion resistance and provides an attractive finish. However, due to its copper content, careful processing during anodizing is necessary. Its weldability is limited, and mechanical fasteners or specialized welding techniques are typically recommended.

In terms of bending and forming, 2030 T4 aluminum alloy offers moderate formability. Its high strength makes complex forming processes more challenging, but successful results can be achieved with proper techniques. Its fatigue resistance and mechanical stability make it ideal for use in high-vibration and dynamically loaded applications. These properties make it a reliable material for long-lasting and durable structures.

Corrosion resistance is naturally moderate, and additional surface treatments or coatings are recommended for use in outdoor or corrosive environments. Advantages of this alloy include excellent machinability, good mechanical strength, and fatigue resistance, while disadvantages include limited weldability, reduced formability, and moderate corrosion resistance. These characteristics make 2030 T4 aluminum alloy an excellent choice for projects requiring precision machining, durability, and high strength.

ALLOY DESIGNATIONS

Aluminium alloy 2030 T4 has similarities to the following standard designations and specifications:

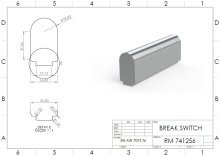

Extruded Round/Flat Bar and Tubes per; 2030 T4, ISO AlCu4PbMg, DIN AlCuMgPb , UNS A92030, ASTM B221, AFNOR AU4Pb

Choosing Factors for 2030 T4

- Strength: High

- Machining: Excellent

- Weldability: Fair

- Formability: Moderate

- Corrosion Resistance: Low

- Heat Treating: Yes

Some Well-Known Applications for 2030 T4

Ski poles,

In the automotive industry,

It is also used in precision machining.

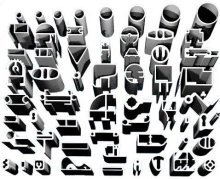

SUPPLIED FORMS

2030 T4 is supplied in round/flat bar and tube/ profile forms.

- Flat/round bar

- Tube/profile

Калькулятор Веса

Калькулятор Веса