Platos

Hojas

Barras Circulares

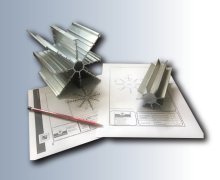

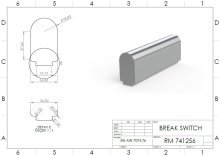

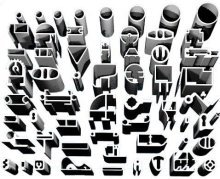

Tubos / Extrusion / Perfil

6063

ASTM B221 / AlMg0.7Si / 6063 / T5

| Chemical Properties | % Value |

| Silicon (Si) | 0,20 - 0,60 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,00 - 0,10 |

| Magnesium (Mg) | 0,45 - 0,90 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,35 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 616 °C |

| Thermal Expansion | 23.4 µm/m.°C |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 210 W/m.K |

| Electrical Resistivity | %53 IACS |

| Mechanical Properties | Value |

| Proof Strength | 145 MPa |

| Yield Strength | 186 MPa |

| Shear Strength | 117 MPa |

| Elongation A50 mm | 12% |

| Hardness | 60 HB |

La aleación de aluminio 6063 T5 es conocida por su excelente maquinabilidad, alta resistencia a la corrosión y ligereza. Se utiliza comúnmente en la construcción, la industria automotriz, la arquitectura y en aplicaciones al aire libre. El temple T5 proporciona buena resistencia y durabilidad gracias al tratamiento térmico, lo que la hace ideal para aplicaciones estructurales y decorativas. El 6063 T5 también es adecuado para el anodizado, lo que mejora el aspecto superficial y aumenta su resistencia a la corrosión.

La soldabilidad del 6063 T5 es bastante buena cuando se utilizan los métodos de soldadura adecuados, lo que la hace popular en los procesos de construcción e industriales. En comparación con el T6, el temple T5 es menos duro, lo que puede facilitar los procesos de soldadura en algunos casos. Además, posee excelentes propiedades de flexión. El 6063 T5 ofrece una gran maquinabilidad, permitiendo un fácil moldeado y curvado, lo que la hace versátil para diversas necesidades de diseño.

La resistencia a la corrosión del 6063 T5 es particularmente alta en condiciones al aire libre y en ambientes agresivos como el agua de mar, lo que contribuye a su larga vida útil y durabilidad. Esta característica la hace ideal para estructuras exteriores. Además, puede utilizarse en entornos con altas vibraciones, lo que la hace adecuada para las industrias automotriz y aeroespacial. Su excelente maquinabilidad y durabilidad contribuyen a la popularidad del 6063 T5.

Las ventajas del 6063 T5 incluyen excelente maquinabilidad, resistencia a la corrosión, compatibilidad con el anodizado, buena soldabilidad y propiedades de flexión. Sin embargo, la menor dureza del temple T5 puede limitar su durabilidad en aplicaciones estructurales de alta carga. A pesar de ello, el 6063 T5 es una opción ideal para muchas aplicaciones que requieren un buen rendimiento, durabilidad y versatilidad.

Como barra o tubo extruido redondo/plano; 6063 T5, AMS QQ-A-200/9, ASTM B221, ASTM B429, UNS A96063, DIN AlMgSi0,5

Factores de elección para 6063 T5

- Resistencia: Media

- Maquinabilidad: Excelente

- Soldabilidad: Muy buena

- Formabilidad: Buena

- Resistencia a la corrosión: Excelente

- Tratamiento térmico: Sí

Algunas aplicaciones conocidas de 6063 T5

En aplicaciones arquitectónicas como marcos de puertas y ventanas,

En sistemas de escaleras y radiadores, así como en componentes de ensamblaje.

También se utiliza en instalaciones neumáticas y ampliamente en sistemas de extrusión.

- Barra / Barra redonda / Barra plana

- Tubo / Perfil

Calculador de Peso

Calculador de Peso