لوحات/ طباقات

صاج

قضيب

أنابيب

7010

ASTM B221 / AlZn6MgCu / 7010 / T74511

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,12 |

| Chromium (Cr) | 0,00 - 0,05 |

| Manganese (Mn) | 0,00 - 0,10 |

| Magnesium (Mg) | 2,10 - 2,60 |

| Copper (Cu) | 1,50 - 2,00 |

| Titanium (Ti) | 0,00 - 0,06 |

| Iron (Fe) | 0,00 - 0,15 |

| Zinc (Zn) | 5,70 - 6,70 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.82 g/cm³ |

| Melting Point | 475 °C |

| Thermal Expansion | 23.7 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | 40% IACS |

| Mechanical Properties | Value |

| Proof Strength | 470 MPa |

| Yield Strength | 530 MPa |

| Shear Strength | 310 MPa |

| Elongation A50 mm | 6% |

| Hardness | 85 HB |

The 7010 T74511 aluminum alloy is known for its high strength, excellent corrosion resistance, and good machinability. It is widely used in applications that require high performance, such as aerospace, defense, and heavy load-bearing structures. The T74511 temper is achieved through heat treatment, which enhances the alloy’s durability and hardness, making it ideal for applications involving heavy loads and high stress. Additionally, 7010 T74511 is suitable for anodizing, which not only enhances its surface appearance but also increases its corrosion resistance.

The weldability of 7010 T74511 is good when the proper welding techniques are used. However, due to its high hardness and strength, welding requires more care and precision, and appropriate welding methods must be applied. In terms of bending, 7010 T74511 may present some challenges due to its high hardness. Although the alloy can be used for bending and shaping, the high strength and hardness require careful handling during the process.

In terms of corrosion resistance, 7010 T74511 performs exceptionally well, especially in harsh environments such as seawater, making it ideal for maritime, outdoor structures, and other applications exposed to corrosion. Additionally, this alloy can be used in high-vibration environments, which makes it advantageous in dynamic industries such as aerospace, defense, and automotive. The high durability and long-lasting performance of 7010 T74511 enhance its reliability in demanding applications.

The advantages of 7010 T74511 aluminum alloy include high mechanical strength, corrosion resistance, anodizing compatibility, weldability, and suitability for high-vibration environments. However, its high hardness and strength may create challenges during welding and bending processes. Additionally, this alloy may not be as easily machinable as more flexible alloys. Despite these drawbacks, 7010 T74511 is an excellent choice for applications that require high performance and durability.

Choosing Factors for 7010 T74511

- Strength: Perfect

- Machining: Average

- Weldability: Weak

- Formability: Weak

- Corrosion Resistance: Excellent

- Heat Treating: Yes

Some Well-Known Applications for 7010 T74511

In ABS braking systems,

In airplane fuselages and wings,

It also has mechanical-chemical applications.

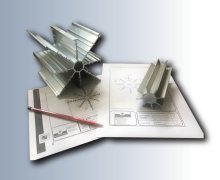

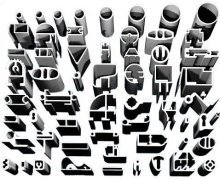

- Round/Flat Bar

- Tube/Profile

حساب الوزن

حساب الوزن