Листы/Плиты

Лист

Бар/Листовая Сталь

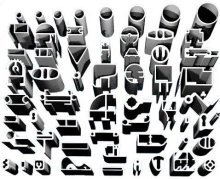

Трубы/Профили

2014A

ASTM B928 / AlCu4SiMg / 2014A / T3510/ T3511

| Chemical Properties | % Value |

| Silicon (Si) | 0,50 - 1,20 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,40 - 1,20 |

| Magnesium (Mg) | 0,20 - 0,80 |

| Copper (Cu) | 3,90 - 5,00 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.80 g/cm³ |

| Melting Point | 507 °C |

| Thermal Expansion | 22.7 µm/m.°C |

| Modulus of Elasticity | 73 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | %34 IACS |

| Mechanical Properties | Value |

| Proof Strength | 320 MPa |

| Yield Strength | 430 MPa |

| Shear Strength | 250 MPa |

| Elongation A50 mm | 7% |

| Hardness | 100 HB |

The 2014A T3510/T3511 aluminum alloys are known for their high strength, good corrosion resistance, and good machinability. The T3510 and T3511 tempers provide high durability and hardness through heat treatment and subsequent cooling. These alloys are commonly used in high-performance structural applications, particularly in industries such as aerospace, defense, and other demanding fields. Additionally, 2014A aluminum alloys are suitable for anodizing, which enhances the surface appearance while increasing corrosion resistance, making them ideal for long-lasting performance in harsh environments like maritime and outdoor applications.

In terms of weldability, 2014A T3510/T3511 aluminum alloys can be successfully welded using proper welding techniques. However, the high hardness of these alloys means that welding requires careful handling. During welding, it is essential to apply proper heat treatment and techniques to avoid issues. In terms of bending, the higher hardness of 2014A alloys makes them more challenging to bend compared to more flexible alloys. However, with the right equipment and techniques, shaping can still be accomplished.

In terms of corrosion resistance, 2014A T3510/T3511 aluminum alloys perform well in harsh environments such as seawater, but may have lower corrosion resistance compared to T6 temper alloys. Nonetheless, they are preferred in aerospace and defense industries due to their good corrosion resistance. Additionally, these alloys can be used in high-vibration environments, making them advantageous in dynamic industries like automotive, aerospace, and defense.

The advantages of 2014A T3510/T3511 aluminum alloys include high mechanical strength, corrosion resistance, anodizing compatibility, weldability, and suitability for high-vibration environments. However, their high hardness can create challenges in welding and bending processes. Additionally, these alloys may not be as easy to machine as more flexible alloys. Despite these challenges, 2014A T3510/T3511 is an excellent choice for industrial applications requiring high performance and durability.

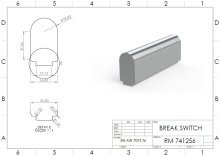

As Cold Drawn Tube: 2014A T3510/ T3511, ASTM B211, UNS A92014, ASTM B928, WNR 3.1255, ISO AlCu4SiMg

Choosing Factors for 2014A T3510/T3511

- Strength: Very good

- Machining: Great

- Weldability: Bad

- Formability: Okay

- Corrosion Resistance: Weak

- Heat Treating: Yes

Some Well-Known Applications for 2014A T3510/T3511

Mainly in the aerospace sector and defense industry,

In the production of military vehicles and weapons,

It is also used in pipelines and the automotive industry.

- Tube/Profile

Калькулятор Веса

Калькулятор Веса