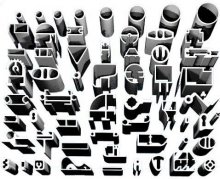

Platten

Blech

Rundstangen

Rohre / Extrusion / Profil

7020

BS H17 / AlZn4,5Mg1 / 7020 / T6

| Chemical Properties | % Value |

| Chromium (Cr) | 0,10 - 0,35 |

| Manganese (Mn) | 0,05 - 0,50 |

| Magnesium (Mg) | 1,00 - 1,40 |

| Copper (Cu) | 0,00 - 0,20 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 4,00 - 5,00 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.78 g/cm³ |

| Melting Point | 605 °C |

| Thermal Expansion | 23,3 x 10^-6 /K |

| Modulus of Elasticity | 71 GPa |

| Mechanical Properties | Value |

| Proof Strength | 310 MPa |

| Yield Strength | 380 MPa |

| Elongation A50 mm | %12 |

| Modulus of Elasticity | 71 GPa |

The alloy EN AW-7020 is a high strength weldable alloy for highly loaded structural applications. The relatively low formability of the alloy limits the complexity of the shapes that can be extruded. Typical applications are highly loaded construction parts, such as in rail transport, aircraft storage containers and mobile cranes.

ALLOY DESIGNATIONS

Aluminium alloy BS H17, 7020 has similarities to the following standard designations and specifications ;

Alloy 7020, UNS A97020, ASTM B209

3.4335

TEMPER TYPES

BS H17, 7020 is supplied in a wide range of tempers:

- T7351 - Solution heat treatment then specially artifically aged for resistance to stress corrosion.

- T7451 - Solution heat-treated, stress-relieved by controlled stretching . The products receive no further straightening after stretching.

- T6 - Solution heat-treated and then artificially aged.

- T7651 - Solution heat-treated, stress-relieved by controlled stretching (permanent set 0.5% to 3% for sheet, 1.5% to 3% for plate, 1% to 3% for rolled or cold-finished rod and bar, 1% to 5% for hand or ring forging and rolled ring) and then artificially overaged in order to achieve a good exfoliation corrosion resistance. The products recieve no further straightening after stretching.

SUPPLIED FORMS

7020 is supplied in plate and bar.

- Plate

- Round Bar / Bar

DELIVERY:

Gewichts-Kalkulator

Gewichts-Kalkulator