Cold Drawn Round Bar

Cold Drawn Tube

6066

Cold Drawn/Finished (CF) / AlMg0.7Si (Soğuk Çekim) / 6066 / T4

| Chemical Properties | % Value |

| Silicon (Si) | 0,90 - 1,80 |

| Chromium (Cr) | 0,00 - 0,40 |

| Manganese (Mn) | 0,60 - 1,10 |

| Magnesium (Mg) | 0,80 - 1,40 |

| Copper (Cu) | 0,70 - 1,20 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,72 g/cm³ |

| Melting Point | 562.8 °C |

| Thermal Expansion | 21.2 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | %40 IACS |

| Mechanical Properties | Value |

| Proof Strength | 190 MPa |

| Yield Strength | 300 MPa |

| Shear Strength | 200 MPa |

| Elongation A50 mm | 16% |

| Hardness | 90 HB |

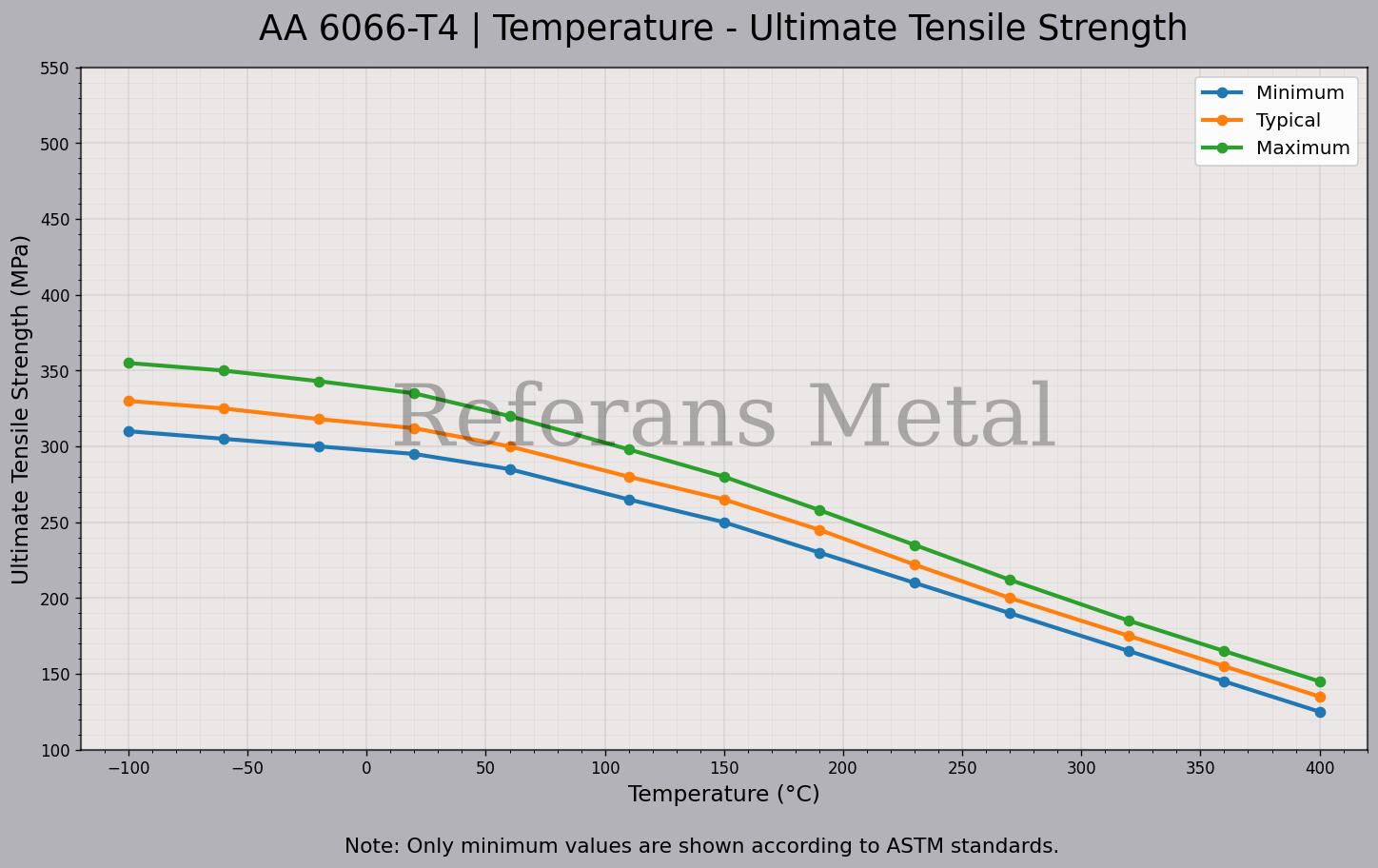

| 6066 T4 Temperature – Tensile Strength Graph |

|

The cold-drawn 6066 T4 aluminum alloy offers excellent corrosion resistance, high strength, and good machinability, making it particularly suitable for harsh outdoor conditions. With these properties, 6066 T4 is widely used in the marine, construction, and automotive sectors. Since this alloy shows excellent resistance to seawater and humid environments, it is frequently chosen for shipbuilding and marine structures. It is also used in construction for transportation systems and structural components.

The 6066 T4 aluminum alloy is suitable for anodizing, which allows for an aesthetic and protective layer on the surface. This process increases the durability of the alloy and provides long-lasting protection against external factors while maintaining a visually appealing appearance. Its weldability is also a significant advantage in production processes. 6066 T4 can be successfully joined using MIG and TIG welding methods, providing design and manufacturing flexibility.

In terms of bendability, 6066 T4 allows the design of various shapes and structures. The alloy is resistant to bending and can be easily formed into the desired shape. Its light weight and durability make it an excellent choice for automotive and aerospace applications in high-vibration environments. It has proven its durability in vehicle chassis and load-bearing components. Its corrosion resistance ensures long-term protection against environmental effects.

The advantages of 6066 T4 aluminum alloy include high corrosion resistance, weldability, and good bendability. However, its disadvantages include reduced strength at high temperatures and limited fatigue resistance. Therefore, 6066 T4 is limited in applications involving high temperatures and heavy fatigue stress. Nevertheless, it is preferred in outdoor applications and the marine industry for its durability and long-lasting performance.

MATERIAL COMPOSITION STANDARDS

6066 T4 can be produced according to the following standards.

• 6066 T4 Cold-Drawn Rod; ASTM B211, UNS A96066, ISO AlMg0.7Si, BS 2 L84

• 6066 T4 Cold-Drawn Tube; ASTM B211, UNS A96066, ISO AlMg0.7Si, BS 2 L84

• 6066 T4 Cold-Drawn Sheet; ASTM B211, UNS A96066, ISO AlMg0.7Si, BS 2 L84

• 6066 T4 Cold-Drawn Wire; ASTM B211, UNS A96066, ISO AlMg0.7Si, BS 2 L84

• 6066 T4 Extrusion Rod; AMS QQ-A-200/10, ASTM B221, UNS A96066, ISO AlMg0.7Si

• 6066 T4 Extrusion Tube; AMS QQ-A-200/10, ASTM B221, UNS A96066, ISO AlMg0.7Si

• 6066 T4 Extrusion Sheet; AMS QQ-A-200/10, ASTM B221, UNS A96066, ISO AlMg0.7Si

• 6066 T4 Extrusion Wire; AMS QQ-A-200/10, ASTM B221, UNS A96066, ISO AlMg0.7Si

CHARACTERISTIC PROPERTIES OF 6066 T4:

- Strength: Upper medium (below 0°C)

- Machinability: Moderate

- Weldability: Medium (Protective arc and filler welding preferred)

- Formability: Very Good

- Corrosion Resistance: Very Good (Increases with coating)

- Heat Treatment: Yes

COMMON APPLICATIONS OF 6066 T4:

Electrical components, interior elements,

Radiators and office furniture,

Also used in pneumatic installations.

STOCK

We supply 6066 T4 in rod/sheet and tube/profile forms.

- Rod / Sheet

- Tube / Profile

Weight Calculator

Weight Calculator