Dalle

Tôle

Barre ronde

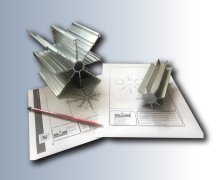

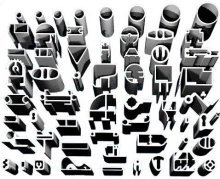

Tube/ Extrusion/ Profil

5083

ASTM B211 / AlMg4.5Mn0.7 / 5083 / H12

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,05 - 0,25 |

| Magnesium (Mg) | 4,00 - 4,90 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.66 g/cm³ |

| Melting Point | 574 °C |

| Thermal Expansion | 22.3 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 120 W/m.K |

| Electrical Resistivity | %29 IACS |

| Mechanical Properties | Value |

| Proof Strength | 250 MPa |

| Yield Strength | 340 MPa |

| Shear Strength | 200 MPa |

| Elongation A50 mm | 5.1% |

| Hardness | 94 HB |

5083 H12 aluminum alloy is known for its high strength, excellent corrosion resistance, and good machinability. Its composition of magnesium, manganese, and chromium makes it highly durable in marine environments, chemically corrosive conditions, and challenging environmental factors. The H12 temper indicates that the alloy is in a semi-hardened state, offering a balanced combination of formability and strength.

This alloy is widely used in marine structures, storage tanks, pressure vessels, chemical transportation containers, and industrial vehicle structures. 5083 H12 is suitable for anodizing, which forms a protective layer on the surface, enhancing its corrosion resistance and providing an attractive finish. It exhibits excellent weldability with TIG and MIG welding techniques, making it ideal for welded constructions.

In terms of bending and forming, 5083 H12 aluminum alloy performs well but requires slightly more care during forming compared to fully softened alloys. Its moderate flexibility minimizes the risk of cracking, making it a reliable choice for detailed shaping and designs. With mechanical stability and fatigue resistance, this alloy is well-suited for high-vibration and dynamically loaded environments.

Advantages of this alloy include outstanding corrosion resistance, good weldability, and lightweight properties, while its disadvantages include not offering as high strength as fully hardened alloys and having limitations in complex forming processes. These characteristics make 5083 H12 aluminum alloy an excellent choice for projects prioritizing durability, lightweight construction, and corrosion resistance.

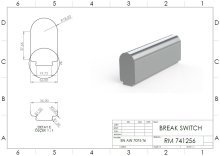

Extruded Round/Flat Bar, Wires and Tubes per; 5083 H12, ASTM B221, AMS QQ-A-200/4, DIN AlMg4.5Mn, ISO AlMg4.5Mn0.7, WNR 3.3547

Cold Drawn Round/Flat Bar, Wires per; 5083 H12, ASTM B211, DIN AlMg4.5Mn, ISO AlMg4.5Mn0.7, WNR 3.3547

Cold Drawn Tubes per; 5083 H12, ASTM B210, DIN AlMg4.5Mn, ISO AlMg4.5Mn0.7, WNR 3.3547

Choosing Factors for 5083 H12

- Strength: Excellent

- Machining: Poor

- Weldability: Okay

- Formability: Moderate

- Corrosion Resistance: Perfect

- Heat Treating: None

Some Well-Known Applications for 5083 H12

In applications requiring light weight and corrosion resistance,

Especially in structural materials in construction and chemical industries,

Also used in automobile chassis.

- Tube/Profile

- Round/Flat Bar

Calculateur de Poids

Calculateur de Poids