Dalle

Tôle

Barre ronde

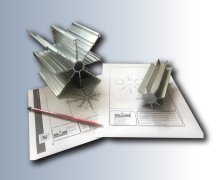

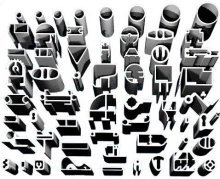

Tube/ Extrusion/ Profil

2007

ASTM B241 / AlCu4PbMgMn / 2007 / T4510

| Chemical Properties | % Value |

| Silicon (Si) | 0,40 Max |

| Copper (Cu) | 3,90 - 5,00 |

| Lead (Pb) | 0,20 - 0,60 |

| Iron (Fe) | 0,70 Max |

| Zinc (Zn) | 0,00 - 0,20 |

| Nickel (Ni) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.82 g/cm³ |

| Melting Point | 510 °C |

| Thermal Expansion | 23 x 10^-6 /K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | %47 IACS |

| Mechanical Properties | Value |

| Proof Strength | 250 MPa |

| Yield Strength | 370 MPa |

| Shear Strength | 230 MPa |

| Elongation A50 mm | 7.8% |

| Hardness | 90 HB |

2007 T4510 aluminum alloy is characterized by excellent machinability, good mechanical strength, and moderate corrosion resistance. With its copper alloy content, this material offers enhanced strength, making it ideal for precision machining and projects requiring high durability. The T4510 temper indicates that the alloy has undergone solution heat treatment and stress-relief processing, ensuring mechanical reliability and stability.

This alloy is widely used in automotive components, aerospace applications, mechanical parts, precision instruments, and high-performance equipment. It is suitable for anodizing, although its copper content necessitates careful processing during the anodizing procedure. Anodized coatings can enhance the alloy’s corrosion resistance while providing an attractive finish. However, its weldability is limited, often favoring mechanical fasteners or specialized welding techniques.

In terms of bending and forming, 2007 T4510 aluminum alloy offers moderate formability. Due to its high strength, complex forming processes require careful handling, but successful results can be achieved with the appropriate techniques. Its fatigue resistance and mechanical stability make it suitable for use in high-vibration environments, making it a reliable option for structures and components subjected to dynamic loads and mechanical stresses.

The alloy’s corrosion resistance is moderate, and additional surface treatments are recommended for outdoor or corrosive conditions. Its advantages include excellent machinability, good mechanical strength, and fatigue resistance, while its disadvantages include limited corrosion resistance, constrained weldability, and moderate formability. These characteristics make 2007 T4510 aluminum alloy an excellent choice for projects requiring lightweight, durability, and precision machining.

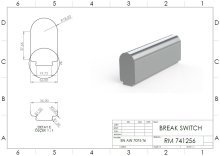

Extruded Round/Flat Bars and Tubes per; 2007 T4510, WNR 3.1645, DIN AlCuMgPb, AFNOR A-U4Pb, UNI 9002/8, UNE L-3121, UNS A92007, ISO AlCu4PbMgMn, ASTM B211

Seamless Extruded Tubes per; 2007 T4510, WNR 3.1645, DIN AlCuMgPb, AFNOR A-U4Pb, UNI 9002/8, UNE L-3121, UNS A92007, ISO AlCu4PbMgMn, ASTM B241

Choosing Factors for 2007 T4510

- Strength: Good

- Machining: Okay

- Weldability: Low

- Formability: Low

- Corrosion Resistance: Low

- Heat Treating: Yes

Some Well-Known Applications for 2007 T4510

In milled and turned parts,

Screw and nut manufacturing,

Also as a component of industrial machines.

- Rod / Round Bar / Flat Bar

- Tube/Profile

Calculateur de Poids

Calculateur de Poids