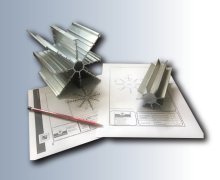

Platos

Hojas

Barras Circulares

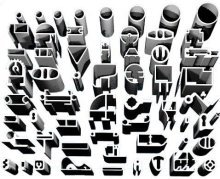

Tubos / Extrusion / Perfil

6063

AMS 4156 / AlMg0.7Si / 6063 / T66

| Chemical Properties | % Value |

| Silicon (Si) | 0,20 - 0,60 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,00 - 0,10 |

| Magnesium (Mg) | 0,45 - 0,90 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,35 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 616 °C |

| Thermal Expansion | 23.4 µm/m.°C |

| Modulus of Elasticity | 68 GPa |

| Thermal Conductivity | 200 W/m.K |

| Electrical Resistivity | 53% IACS |

| Mechanical Properties | Value |

| Proof Strength | 170 MPa |

| Yield Strength | 210 MPa |

| Shear Strength | 152 MPa |

| Elongation A50 mm | 6% |

| Hardness | 75 HB |

6063 T66 aluminum alloy is known for its excellent corrosion resistance, superior surface finish, and enhanced mechanical properties. The T66 temper, a refined version of T6, provides slightly higher strength and hardness. It is highly suitable for anodizing, offering both aesthetic appeal and improved corrosion protection, making it ideal for architectural and structural applications such as window frames and facade systems.

It can be successfully welded with appropriate techniques and controlled heat input. Though its high strength makes bending more challenging, proper equipment and methods allow effective forming. Its excellent durability in harsh environments, including marine and industrial settings, makes it a strong candidate for outdoor, marine, automotive, and aerospace applications.

Despite being slightly more difficult to machine than softer alloys, 6063 T66 is a top choice for projects demanding both performance and aesthetics.

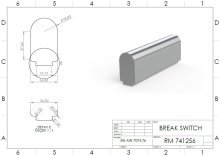

As Extruded Seamless Tube;6063 T66, AMS QQ-A-200/9, ASTM B345, ASTM B241, ISO AlMg0.7Si

As Extruded Round/Flat Bar; 6063 T66, AMS QQ-A-200/9, AMS 4156, ASTM B221 , ASTM B429, ISO AlMg0.7Si, DTD 372B

As Cold Drawn Round/Flat Bar: 6063 T66, ASTM B483, ASTM B211, WNR 3.32206, ISO AlMg0.7Si

Choosing Factors for 6063 T66

- Strength: Average

- Machining: Good

- Weldability: Very good

- Formability: Okay

- Corrosion Resistance: Good

- Heat Treating: Yes

Some Well-Known Applications for 6063 T66

In architectural façade applications

As a component of metal decorative elements

It is also used in the automotive and aerospace industries

- Rod / Round Bar / Flat Bar

- Tube/Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 10.0 up to & incl. 25.0 mm | 180 MPa | 225 MPa | 6% |

Calculador de Peso

Calculador de Peso