Platten

Blech

Rundstangen

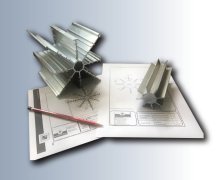

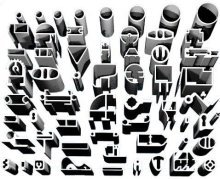

Rohre/ Extrusion/ Profil

2219

AMS 4031 / AlCu6Mn / 2219 / O

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,20 |

| Manganese (Mn) | 0,20 - 0,40 |

| Magnesium (Mg) | 0,00 - 0,02 |

| Copper (Cu) | 5,80 - 6,80 |

| Titanium (Ti) | 0,02 - 0,10 |

| Iron (Fe) | 0,00 - 0,30 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,84 g/cm³ |

| Melting Point | 543 °C |

| Thermal Expansion | 22.3 µm/m.°C |

| Modulus of Elasticity | 74 GPa |

| Thermal Conductivity | 171 W/m.K |

| Electrical Resistivity | 44 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 75.8 MPa |

| Yield Strength | 172 MPa |

| Shear Strength | 106 MPa |

| Elongation A50 mm | 15% |

| Hardness | 46 HB |

The 2219 O aluminum alloy is well-known for its high-temperature resistance and excellent weldability. As part of the aluminum-copper alloy family, 2219 is widely used in applications requiring high performance and durability. The O temper indicates that the alloy is in a soft, annealed condition without heat treatment, providing advantages in machinability and formability. With its strength and thermal stability, 2219 O is commonly employed in the aerospace and space industries.

In terms of anodizing, the 2219 O aluminum alloy has limited suitability due to its high copper content. The copper reduces the formation of an effective oxide layer during anodizing, making surface protection through anodizing more challenging. Instead, surface protection is typically achieved using alternative coatings or specialized surface treatments. In terms of weldability, the 2219 O aluminum alloy excels, making it a popular choice for aerospace applications. Proper welding techniques can minimize the risk of cracking during the welding process.

When it comes to bending and forming, the soft structure of the 2219 O aluminum alloy allows for excellent formability, facilitating the production of complex shapes. This makes it suitable for flexible design requirements. Its use in high-vibration environments is supported by its thermal stability and structural integrity, which ensure long-term durability. These properties make it an ideal choice for structures subjected to dynamic loads and high vibration.

Regarding corrosion resistance, the 2219 O aluminum alloy has limitations compared to other aluminum alloys due to its copper content, which reduces corrosion resistance. However, these limitations can be mitigated through proper surface treatments and coatings. Its advantages include high-temperature resistance, excellent weldability, and good formability, while its disadvantages include limited corrosion resistance and low suitability for anodizing. These characteristics make 2219 O an excellent material for projects where thermal resistance and structural reliability are critical.

As Extruded Round/Flat Bar and Tube: 2219 O, ASTM B221, UNS A92219, ISO AlCu6Mn

As Plate/Sheet; 2219 O, ASTM B209, UNS A92219, AMS 4031, AMS QQ-A-250/30A, ISO AlCu6Mn

Choosing Factors for 2219 O

- Strength: Moderate

- Machining: Poor

- Weldability: Very good

- Formability: Good

- Corrosion Resistance: Satisfactory

- Heat Treating: Yes

Some Well-Known Applications for 2219 O

In the aerospace industry,

As a structural component of aircraft skins,

It is also used in rocket boosters.

- Rod / Round Bar / Flat Bar

- Plate/Sheet

- Tube/Profile

Gewichts-Kalkulator

Gewichts-Kalkulator