Dalle

Tôle

Barre ronde

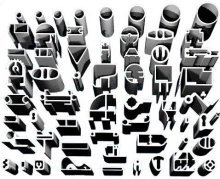

Tube/ Extrusion/ Profil

2219

AMS QQ-A-250/30 / AlCu6Mn / 2219 / T87

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,20 |

| Manganese (Mn) | 0,20 - 0,40 |

| Magnesium (Mg) | 0,00 - 0,02 |

| Copper (Cu) | 5,80 - 6,80 |

| Titanium (Ti) | 0,02 - 0,25 |

| Iron (Fe) | 0,00 - 0,30 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.85 g/cm³ |

| Melting Point | 543 °C |

| Thermal Expansion | 22.3 µm/m-°C |

| Modulus of Elasticity | 73.1 GPa |

| Thermal Conductivity | 120 W/m.K |

| Electrical Resistivity | 29% IACS |

| Mechanical Properties | Value |

| Proof Strength | 390 MPa |

| Yield Strength | 480 MPa |

| Shear Strength | 280 MPa |

| Elongation A50 mm | 7% |

| Hardness | 130 HB |

The 2219 T87 aluminum alloy is known for its high strength and durability. Belonging to the aluminum-copper alloy class, this material is primarily used in high-performance industries such as aerospace, space, and military applications. The T87 temper, achieved through a specific heat treatment process, enhances the alloy's durability, offering high strength and lightweight properties. The 2219 T87 is commonly used in structural components that require high performance in demanding conditions.

The 2219 T87 alloy has limited suitability for anodizing. Its high copper content prevents the formation of a strong oxide layer during the anodizing process. Therefore, alternative protective coatings are typically used instead of anodizing. In terms of weldability, the 2219 T87 alloy requires careful welding processes due to its high copper content. The increased risk of cracking during welding can be minimized by using special welding techniques and appropriate filler materials.

Regarding bending and forming, the 2219 T87 aluminum alloy requires careful processing due to its high strength. However, with the right techniques, successful bending and shaping can be achieved. Additionally, the alloy is suitable for use in high-vibration environments. Its high durability and elastic modulus make it ideal for components such as engine parts, aircraft structural components, and other parts exposed to vibrations.

In terms of corrosion resistance, the 2219 T87 aluminum alloy has limited resistance due to its high copper content. This can limit its use in harsh environments, such as marine and humid conditions. However, these limitations can be overcome with proper coating methods and surface treatments to enhance the alloy's corrosion resistance. The advantages of the 2219 T87 alloy include high strength, lightweight, and durability, while its drawbacks include lower corrosion resistance and welding challenges.

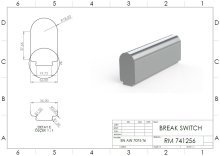

As Sheet/Plate; 2219 T87, ASTM B209, UNS A92219, ISO AlCu6Mn, AMS 4295D, MIL-A-22771

Choosing Factors for 2219 T87

- Strength: Great

- Machining: Weak

- Weldability: Very good

- Formability: Okay

- Corrosion Resistance: Good

- Heat Treating: Yes

Some Well-Known Applications for 2219 T87

It has many uses, from camping equipment to pressurized tanks.

In landing gear and engine frames,

It is also used in high-strength weldaments in the aerospace industry.

- Sheet

- Plate

Calculateur de Poids

Calculateur de Poids