Platten

Blech

Rundstangen

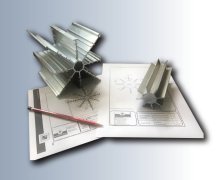

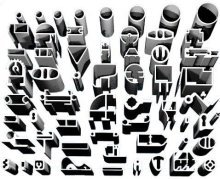

Rohre/ Extrusion/ Profil

7178

AMS QQ-A-250/14 / AlZn7MgCu / 7178 / T6

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,40 - 3,10 |

| Copper (Cu) | 1,60 - 2,40 |

| Titanium (Ti) | 0,00 - 0,20 / - |

| Iron (Fe) | 0,00 - 0,15 |

| Zinc (Zn) | 6,30 - 7,30 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,83 g/cm³ |

| Melting Point | 468 °C |

| Thermal Expansion | 23.4 µm/m.°C |

| Modulus of Elasticity | 71.7 GPa |

| Thermal Conductivity | 125 W/m.K |

| Electrical Resistivity | 30% IACS |

| Mechanical Properties | Value |

| Proof Strength | 490 MPa |

| Yield Strength | 558 MPa |

| Shear Strength | 380 MPa |

| Elongation A50 mm | %10 |

| Hardness | 160 HB |

7178 T6 aluminum alloy is a high-strength material known for its excellent fatigue resistance and durability. With its zinc and magnesium content, 7178 T6 is widely used in high-performance applications. The T6 temper signifies that the alloy has undergone solution heat treatment followed by artificial aging, enhancing its strength and hardness. This makes it an ideal material for load-bearing and dynamically stressed structures.

7178 T6 is particularly utilized in aerospace, defense, and automotive industries for critical applications. It is commonly found in aircraft structures, military vehicles, space technology, and high-performance equipment, where its high strength and lightweight properties offer significant advantages. The alloy is suitable for anodizing, forming a smooth oxide layer that enhances corrosion resistance and provides an aesthetic surface. However, its high zinc content requires careful handling during the anodizing process.

In terms of bending and forming, 7178 T6 has limitations due to its high strength. Complex shaping processes may pose a risk of cracking, making the use of appropriate techniques crucial. Its excellent fatigue resistance and mechanical stability make it ideal for use in high-vibration environments. It ensures long-term reliability in dynamically loaded structures and equipment.

Corrosion resistance is moderate, and additional protective treatments or coatings may be necessary for use in corrosive environments. Advantages of 7178 T6 include high strength, excellent fatigue resistance, and anodizing compatibility, while disadvantages include limited formability, poor weldability, and lower natural corrosion resistance. These characteristics make 7178 T6 an excellent choice for applications requiring lightweight, durability, and high performance.

As Sheet; 7178 T6, ASTM B209, SAE J454, AMS QQ-A-250/14, QQ-A-430, UNS A 97178, ISO AlZn7MgCu

Choosing Factors for 7178 T6

- Strength: High

- Machining: Weak

- Weldability: Fair

- Formability: Good

- Corrosion Resistance: Good

- Heat Treating: Yes

Some Well-Known Applications for 7178 T6

In the construction and aerospace industry,

On aircraft fuselages,

It has many uses, including high-strength fittings.

- Sheet

Gewichts-Kalkulator

Gewichts-Kalkulator