Dalle

Tôle

Barre ronde

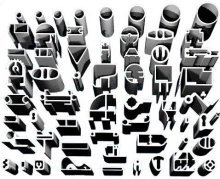

Tube/ Extrusion/ Profil

5086

QQ-A-250/7 / AlMg4 / 5086 / H116

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Manganese (Mn) | 0,20 - 0,70 |

| Magnesium (Mg) | 3,50 - 4,50 |

| Copper (Cu) | 0,00 - 0,10 |

| Chromium (Cr) | 0,05 - 0,25 |

| Zinc (Zn) | 0,00 - 0,25 |

| Iron (Fe) | 0,00 - 0,50 |

| Physical Properties | Value |

| Density | 2,66 g/cm³ |

| Melting Point | 585 °C |

| Thermal Expansion | 22.0 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | %31 IACS |

| Mechanical Properties | Value |

| Proof Strength | 207 MPa |

| Yield Strength | 280 MPa |

| Shear Strength | 176 MPa |

| Elongation A50 mm | %11 |

| Hardness | 78 HB |

5086 H116 aluminum alloy is known for its high strength, excellent corrosion resistance, and good weldability. With its magnesium content, this alloy is particularly well-suited for marine, defense, and transportation sectors, especially in applications exposed to corrosive environments such as seawater. The H116 temper signifies that the alloy has been mechanically hardened and stabilized specifically for marine applications.

5086 H116 is widely used in ship hulls, offshore platforms, fuel tanks, military vehicle armor, and pressure vessels, where durability in harsh conditions is essential. It is suitable for anodizing, creating an aesthetic oxide layer that enhances corrosion resistance. The alloy also exhibits excellent weldability and can be easily joined using standard welding techniques like MIG or TIG. After welding, it retains much of its strength, making it ideal for structural applications.

In terms of bending and forming, 5086 H116 aluminum alloy is well-suited for creating complex shapes. Although its high strength requires careful handling during processing, successful results can be achieved with proper techniques. It is highly suitable for high-vibration environments due to its excellent fatigue resistance and mechanical stability, ensuring long-term durability. These characteristics make it a reliable material for structures and equipment exposed to dynamic loads and vibrations.

Corrosion resistance is one of the standout features of 5086 H116. It offers exceptional durability against saltwater, humid environments, and chemicals, making it an excellent choice for marine and outdoor applications. However, compared to higher-strength alloys, it has a relatively limited load-bearing capacity, which can be a disadvantage in some applications. Its advantages include high corrosion resistance, good weldability, and formability, while its disadvantages include the need for careful handling during shaping and limited load-bearing capacity. These properties make 5086 H116 an ideal material for projects requiring lightweight, durability, and reliability.

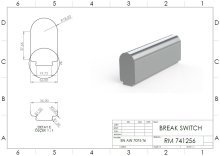

As Plate/Sheet; 5086 H116, AMS QQ-A-250/7, ASTM B209, ISO AlMg4, DIN AlMg4Mn UNS A95086, ASTM B632, ASTM B928, AMS QQ-A-250/19, WNR 3.3545

Choosing Factors for 5086 H116

- Strength: Good

- Machining: Very good

- Weldability: Excellent

- Formability: Fairly good

- Corrosion Resistance: Great

- Heat Treating: Yes

Some Well-Known Applications for 5086 H116

It is used especially in marine materials and superstructures, decks,

As a structural component of missiles and tanks in the defense industry,

It is also widely used in communication, radio, TV towers and drilling rigs.

- Plate

- Sheet

Calculateur de Poids

Calculateur de Poids