Platten

Blech

Rundstangen

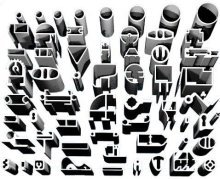

Rohre/ Extrusion/ Profil

5182

ASTM B209 / AlMg4.5Mn0.4 / 5182 / H111

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,25 |

| Chromium (Cr) | 0,15 - 0,35 |

| Manganese (Mn) | 0,00 - 0,10 |

| Magnesium (Mg) | 3,10 - 3,90 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,66 g/cm³ |

| Melting Point | 595 °C |

| Thermal Expansion | 23.8 µm/m-°C |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | %32 IACS |

| Mechanical Properties | Value |

| Proof Strength | 130 MPa |

| Yield Strength | 280 MPa |

| Shear Strength | 170 MPa |

| Elongation A50 mm | %14 |

| Hardness | 69 HB |

The 5182 H111 aluminum alloy is known for its excellent corrosion resistance, good machinability, and moderate strength. As part of the aluminum-magnesium alloy class, it is commonly used in industries such as maritime, automotive, construction, and other applications exposed to harsh environmental conditions. The H111 temper provides medium hardness to the alloy, enhancing its durability while maintaining flexibility. Its lightweight and strong structure make it an ideal material for use in maritime and outdoor applications.

ALLOY DESIGNATIONS

5182 H111 has the following standard designations and specifications.

Sheets per; 5182 H111, ISO AlMg4.5Mn0.4, DIN AlMg5Mn, WNR 3.3549, UNS A95182, ASTM B209

Choosing Factors for 5182 H111

- Strength: Mediocre

- Machining: Very good

- Weldability: Good

- Formability: Good

- Corrosion Resistance: Perfect

- Heat Treating: None

Some Well-Known Applications for 5182 H111

In the construction of structural and inner panels of automobiles,

In aluminum cans,

It is also used in brackets and parts.

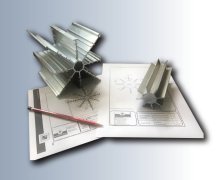

SUPPLIED FORMS

5182 H111 is produced/supplied in sheet round/flat bar and tube/profile forms.

- Sheet

DELIVERY:

Gewichts-Kalkulator

Gewichts-Kalkulator