Platten

Blech

Rundstangen

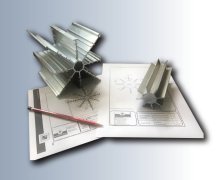

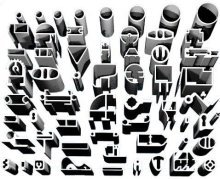

Rohre/ Extrusion/ Profil

5251

ASTM B211 / AlMg2Mn0.3 / 5251 / H14

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,00 - 0,15 |

| Manganese (Mn) | 0,10 - 0,50 |

| Magnesium (Mg) | 1,70 - 2,40 |

| Copper (Cu) | 0,00 - 0,15 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,15 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,69 g/cm³ |

| Melting Point | 605 °C |

| Thermal Expansion | 23.6 µm/m.°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | %38 IACS |

| Mechanical Properties | Value |

| Proof Strength | 190 MPa |

| Yield Strength | 220 MPa |

| Shear Strength | 130 MPa |

| Elongation A50 mm | 5% |

| Hardness | 64 HB |

Aluminium alloy 5251 is a medium strength alloy possessing good ductility and therefore good formability. Alloy 5251 is known for work hardening rapidly and is readily weldable. It also possesses high corrosion resistance particularly in marine environments.

Extruded Round/Flat Bars and Tubes per; 5251 H14, ISO AlMg2Mn0.3, DIN AlMg2, WNR 3.3525, UNE L-3361, A-G2M, ASTM B209, UNS A95251

Cold Drawn Round/Flat Bars per; 5251 H14, ISO AlMg2Mn0.3, ASTM B211, UNS A95251, DIN AlMg2, WNR 3.3525, BS 3 L56

Choosing Factors for 5251 H14

- Strength: Average

- Machining: Mediocre

- Weldability: Excellent

- Formability: Okay

- Corrosion Resistance: Very good

- Heat Treating: None

Some Well-Known Applications for 5251 H14

In car panels in the automotive industry.

In furniture tubings,

It is also used in silo bunkers.

SUPPLIED FORMS

- Round/Flat Bar

- Tube/Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 0,2 up to & incl. 0,5 | 170 | 270 | %3 |

| Over 0,5 up to & incl. 1,2 | 170 | 270 | %4 |

| Over 1,5 up to & incl. 3,0 | 170 | 270 | %5 |

| Over 3,0 up to & incl. 4,0 | 170 | 270 | %7 |

Gewichts-Kalkulator

Gewichts-Kalkulator