5454

ASTM B209 / AlMg3Mn / 5454 / H24

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,25 |

| Chromium (Cr) | 0,05 - 0,20 |

| Manganese (Mn) | 0,50 - 1,00 |

| Magnesium (Mg) | 2,40 - 3,00 |

| Copper (Cu) | 0,0 - 0,10 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.69 g/cm³ |

| Melting Point | 602 °C |

| Thermal Expansion | 23.6 µm/m.°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | %34 IACS |

| Mechanical Properties | Value |

| Proof Strength | 230 MPa |

| Yield Strength | 290 MPa |

| Shear Strength | 170 MPa |

| Elongation A50 mm | 5% |

| Hardness | 80 HB |

This alloy is primarily used in areas where good formability is required, it is used in O, H112, H32, H34, H24, H22;

to specification ASTM B209 Tempers and is an excellent choice for large pressure vessels and certain marine fabricated products. The formability is at its best in the soft 0 temper, but also sometimes used in H32 or H34 tempers too. However the strength and corrosion resistance are not always as good as other alloys, so as always a marine structural engineer should be consulted for each application.

to specification ASTM B209 Tempers and is an excellent choice for large pressure vessels and certain marine fabricated products. The formability is at its best in the soft 0 temper, but also sometimes used in H32 or H34 tempers too. However the strength and corrosion resistance are not always as good as other alloys, so as always a marine structural engineer should be consulted for each application.

ALLOY DESIGNATIONS

5454 H24 has the following standard designations and specifications.

Sheets per; 5454 H24, ISO AlMg3Mn, DIN AlMg2.7Mn, WNR 3.3537, UNS A95454, ASTM B209, AMS QQ-A-250/10

Extruded Round/Flat Bar and Tubes per; 5454 H24, ISO AlMg3Mn, DIN AlMg2.7Mn, WNR 3.3537, UNS A95454, ASTM B221, AMS QQ-A-200/6

Choosing Factors for 5454 H24

- Strength: Mediocre

- Machining: Satisfactory

- Weldability: Okay

- Formability: Perfect

- Corrosion Resistance: Perfect

- Heat Treating: None

Some Well-Known Applications for 5454 H24

It is widely used in architectural facades,

Truck and truck chassis,

Mechanical and chemical industry.

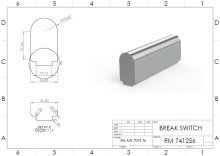

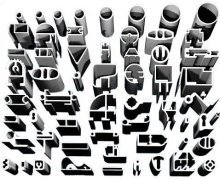

SUPPLIED FORMS

5454 H24 is produced/supplied in the sheet, tube/profile, round/flat bar forms.

- Sheet

- Round/Flat Bar

- Tube/Profile

DELIVERY:

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 0.2 up to & incl. 0.5 | 270 MPa | 325 MPa | %4 |

| Over 0.5 up to & incl. 1.5 | 270 MPa | 325 MPa | %5 |

| Over 1.5 up to & incl. 3.0 | 270 MPa | 325 MPa | %6 |

| Over 3.0 up to & incl. 6.0 | 270 MPa | 325 MPa | %7 |

| Over 6.0 up to & incl. 12.5 | 270 MPa | 325 MPa | %8 |

| Over 12,5 up to & incl. 25,0 | 270 MPa | 325 MPa | %7 |

حساب الوزن

حساب الوزن