6061

EN 2694 / AlMg1SiCu / 6061 / T62

| Chemical Properties | % Value |

| Silicon (Si) | 0,40 - 0,80 |

| Chromium (Cr) | 0,04 - 0,35 |

| Manganese (Mn) | 0,00 - 0,15 |

| Magnesium (Mg) | 0,80 - 1,20 |

| Copper (Cu) | 0,15 - 0,40 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,70 g/cm³ |

| Melting Point | 582 °C |

| Thermal Expansion | 23.6 µm/m.°C |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 167 W/m.K |

| Electrical Resistivity | 43% IACS |

| Mechanical Properties | Value |

| Proof Strength | 270 MPa |

| Yield Strength | 320 MPa |

| Shear Strength | 190 MPa |

| Elongation A50 mm | 9% |

| Hardness | 88 HB |

6061 T62 aluminum exhibits mid strength and is widely used in aerospace applications.

ALLOY DESIGNATIONS

6061 T62 has the following standard designations and specifications.

As Plate/Sheet; 6061 T62, EN 2694, UNS A96061, WNR 3.3211, ISO AlMg1SiCu, ASTM B209

Choosing Factors for 6061 T62

- Strength: Mediocre

- Machining: Good

- Weldability: Exquisite

- Formability: Okay

- Corrosion Resistance: Great

- Heat Treating: Yes

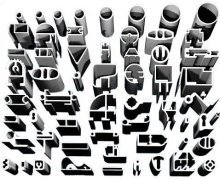

Some Well-Known Applications for 6061 T62

In applications requiring high pressure, in tank fittings,

In motor boats and railway wagons,

It is also used in the aerospace sector, especially in helicopter and aircraft parts.

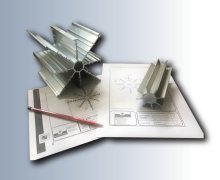

SUPPLIED FORMS

6061 T62 is produced/supplied in sheet form.

- Sheet

- Plate

DELIVERY:

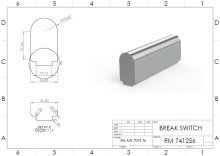

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 12.5 up to & incl. 40.00 | 240 | 290 | %8 |

| Over 40.00 up to & incl. 80.00 | 240 | 290 | %6 |

| Over 80.00 up to & incl. 100.00 | 240 | 290 | %5 |

| Over 100.00 up to & incl. 150.00 | 240 | 275 | %5 |

| Over 150.00 up to & incl. 175.00 | 230 | 265 | %5 |

حساب الوزن

حساب الوزن