Barres Étirées à Froid

Tubes Étirés à Froid

6082

Cold Drawn/Finished (CF) / AlSi1MgMn (Soğuk Çekim) / 6082 / T4

| Chemical Properties | % Value |

| Silicon (Si) | 0,70 - 1,30 |

| Chromium (Cr) | 0,00 - 0,25 |

| Manganese (Mn) | 0,40 - 1,00 |

| Magnesium (Mg) | 0,60 - 1,20 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.71 g/cm³ |

| Melting Point | 575 °C |

| Thermal Expansion | 23.1 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 170 W/m.K |

| Electrical Resistivity | 42% IACS |

| Mechanical Properties | Value |

| Proof Strength | 120 MPa |

| Yield Strength | 205 MPa |

| Shear Strength | 126 MPa |

| Elongation A50 mm | %16 |

| Hardness | 58 HB |

The cold-drawn 6082 T4 aluminum alloy is known for its high strength, excellent machinability, and superior corrosion resistance. These features make it an ideal choice for demanding industrial applications such as construction, automotive, mechanical engineering, and maritime industries. 6082 T4 is commonly used in projects requiring high structural strength, such as bridges, cranes, transport systems, and automotive parts.

One of the key advantages of the 6082 T4 alloy is its suitability for anodizing. The anodizing process allows the alloy to be both aesthetically enhanced and protected from external factors, offering an attractive, durable finish that improves its corrosion resistance. Additionally, the alloy’s weldability provides great flexibility in design and manufacturing processes. High-quality welds can be achieved using methods like MIG and TIG welding, making it a versatile material for a variety of applications.

The 6082 T4 alloy is also highly suitable for bending. With its low bending resistance and high deformability, it can be shaped into a variety of forms, which is particularly advantageous for automotive and construction applications. Moreover, this alloy performs excellently in high-vibration environments. It is an ideal choice for components exposed to vibration and impact, making it a preferred material in the automotive industry and transportation systems.

When it comes to corrosion resistance, 6082 T4 aluminum alloy shows exceptional durability against harsh conditions such as seawater and atmospheric moisture. This property makes it a great option for marine and outdoor applications.

Among the advantages of 6082 T4 are its high strength, corrosion resistance, weldability, and bendability. However, there are some disadvantages to consider. Under high-temperature or excessive loading conditions, the alloy’s mechanical properties can be compromised. Additionally, in certain applications, its fatigue resistance may not be as effective as that of alloys with higher durability. Despite these drawbacks, the 6082 T4 aluminum alloy remains an excellent choice for structural and engineering applications.

As Sheet/Plate; 6082 T4,, ISO AlSi1MgMn, ASTM B209, UNS A96082, WNR 3.2315

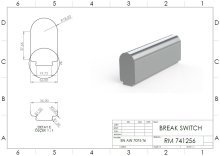

As Extruded Round/Flat Bar, Tube ; 6082 T4, ISO AlSi1MgMn, ASTM B221, UNS A96082, WNR 3.2315

As Cold Drawn Round/Flar Bar, Tube: 6082 T4, ISO AlSi1MgMn, ASTM B211, UNS A96082, WNR 3.2315

Choosing Factors for 6082 T4

- Strength: Very good

- Machining: Mediocre

- Weldability: Good

- Formability: Good

- Corrosion Resistance: Exquisite

- Heat Treating: Yes

Some Well-Known Applications for 6082 T4

In structural component requiring high stress,

In maritime and sea boats,

It is also used in bicycle manufacturing and the machinery industry.

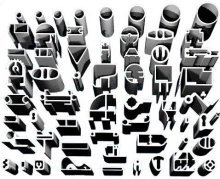

- Plate/ Sheet

- Rod / Round Bar / Flat Bar

- Tube/Profile

Calculateur de Poids

Calculateur de Poids