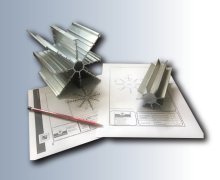

Platos

Hojas

Barras Circulares

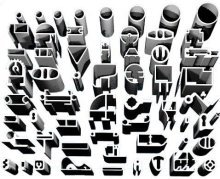

Tubos / Extrusion / Perfil

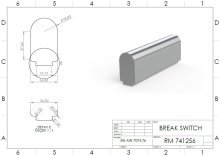

7050 clad

AMS 4243 / AlZn6CuMgZr / 7050 clad / T76

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,12 |

| Chromium (Cr) | 0,00 - 0,04 |

| Manganese (Mn) | 0,00 - 0,10 |

| Magnesium (Mg) | 1,90 - 2,60 |

| Copper (Cu) | 2,00 - 2,60 |

| Titanium (Ti) | 0,08 - 0,21 |

| Iron (Fe) | 0,00 - 0,15 |

| Zinc (Zn) | 5,70 - 6,70 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,80 g/cm³ |

| Melting Point | 488 °C |

| Thermal Expansion | 21.7 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 153 W/m-K |

| Electrical Resistivity | 35 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 500 MPa |

| Yield Strength | 552 MPa |

| Shear Strength | 330 MPa |

| Elongation A50 mm | 11% |

| Hardness | 147 HB |

7050 Clad T76 aluminum alloy is a high-strength material known for its excellent corrosion resistance, fatigue performance, and durability under extreme conditions. The clad version features a thin layer of pure aluminum on the surface, enhancing its corrosion resistance while maintaining the strength of the core 7050 alloy. The T76 temper indicates that the material has undergone solution heat treatment and overaging processes to achieve optimal strength and stress-corrosion cracking resistance, making it ideal for demanding applications.

This alloy is widely used in the aerospace and defense industries for components such as wing skins, fuselage panels, and other structural parts requiring high strength and durability. It is also employed in high-performance industrial equipment. 7050 Clad T76 has good compatibility with anodizing, providing a uniform and protective oxide layer that enhances its corrosion resistance and offers a polished aesthetic. While welding is possible, its high strength can make welding more challenging, requiring skilled techniques and careful filler material selection.

In terms of bending and forming, 7050 Clad T76 offers moderate formability, as its high strength can limit its ability to handle complex shapes without cracking. However, with proper techniques, it can be successfully shaped for precise applications. The alloy excels in high-vibration environments due to its superior fatigue resistance, making it suitable for structures exposed to dynamic loads and stress over time.

The corrosion resistance of 7050 Clad T76 is further enhanced by its clad layer, making it highly reliable in harsh environments, including marine and industrial settings. Despite its excellent properties, its high strength can make machining and forming more challenging compared to lower-strength alloys. Advantages include exceptional strength, improved stress-corrosion cracking resistance, and enhanced fatigue performance, while disadvantages include limited formability and a need for skilled handling during processing. These characteristics make 7050 Clad T76 an ideal material for critical applications requiring a balance of strength, corrosion resistance, and durability.

Choosing Factors for 7050 T76 clad

- Strength: Excellent

- Machining: Okay

- Weldability: Low

- Formability: Medium

- Corrosion Resistance: Very good

- Heat Treating: Yes

Some Well-Known Applications for 7050 T76 clad

In aircraft as floor beams,

In motorcycle and bicycle body frames,

There are also marine and nuclear industry applications.

- Sheet

Calculador de Peso

Calculador de Peso