Листы/Плиты

Лист

Бар/Листовая Сталь

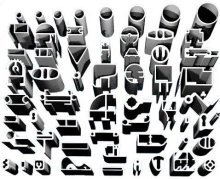

Трубы/Профили

7075

AMS 4044 / AlZn5.5MgCu / 7075 / O

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.81 g/cm³ |

| Melting Point | 477°C |

| Thermal Expansion | 23 x 10^-6 /K |

| Modulus of Elasticity | 71.7 GPa |

| Thermal Conductivity | 173 W/m.K |

| Electrical Resistivity | %33 IACS |

| Mechanical Properties | Value |

| Proof Strength | 120 MPa |

| Yield Strength | 240 MPa |

| Shear Strength | 150 MPa |

| Elongation A50 mm | %12 |

| Hardness | 71.7 GPa |

7075 O aluminum alloy is a variant of the 7075 series known for its high strength potential, presented in the annealed (O) condition. This state makes the alloy softer and more formable, enabling the easy shaping of parts with complex geometries. Commonly serving as a foundational material in the aerospace, automotive, defense, and sports equipment industries, 7075 O is often considered a starting point that can subsequently be heat-treated to achieve higher strength values.

The alloy’s surface is suitable for anodizing, thereby enhancing both corrosion resistance and aesthetic appeal. In its O condition, 7075 offers better weldability compared to heat-treated conditions like T6 or T7, as the softer, stress-free state reduces the risk of cracks in the weld zone. Similarly, the annealed structure facilitates bending and other cold-forming processes, allowing manufacturers to smoothly transition to different shapes as needed.

Although 7075 O is flexible and easily formable, achieving the high strength and fatigue resistance required in vibration-prone environments typically depends on subsequent heat treatments. Even so, it inherently provides good corrosion resistance, which can be further improved with appropriate surface coatings. This makes it an attractive choice even under harsh conditions, such as marine or humid environments, where long-term structural integrity is essential.

Among its advantages are high strength potential, excellent formability, suitability for anodizing, and relatively favorable welding conditions. However, in its O state, the alloy has not yet reached its full strength capacity, which is why final applications often involve products that are heat-treated after shaping. Additionally, for end products requiring very high strength, proper heat and surface treatments are essential. This balance allows 7075 O to offer both manufacturing ease and the potential for enhanced performance, making it a strategic alloy choice.

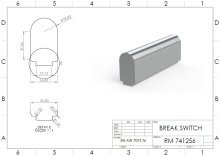

Sheet as; AMS QQ-A-250/12, AMS 4044,ASTM B209

Alclad Sheet as; AMS QQ-A-250/13,AMS 4048,ASTM B209,WL 3.4374,DAN 424,EN 2092

Oneside Alclad Sheet as; AMS QQ-A-250/18,ASTM B209

Extrusion Seamless Pipe as; AMS QQ-A-200/11,ASTM B241

Cold Drawn as Rod,Flat Bar,Wire as; AMS QQ-A-255/9,AMS 4187,ASTM B211

Cold Drawn Seamless Pipe as; AMS-T-700/7,DIN 3.4365, A-Z5GU

Choosing Factors for 7075 O

- Strength: Average

- Machining: Poor

- Weldability: Normal

- Formability: Weak

- Corrosion Resistance: Moderate

- Heat Treating:No

Some Well-Known Applications for 7075 O:

In part that need quick change in various project,especially in military project .

Chasis for bicyles and similar light mobile vehicles.

Mechanisms like locks and keys.

- Plate

- Sheet

- Rod / Round Bar / Flat Bar

- Tube / Extrusions / Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| over 0.203 up to & incl. 1.57 | 136 MPa | 246 MPa | 9.0 - 10 |

| over 1.60 up to & incl. 4.75 | 137 MPa | 260 MPa | 10 |

| over 4.78 up to & incl. 12.7 | 143 MPa | 267 MPa | 10 |

| over 12.7 up to & incl. 25.4 | 150 MPa | 274 MPa | 10 |

Калькулятор Веса

Калькулятор Веса