Листы/Плиты

Лист

Бар/Листовая Сталь

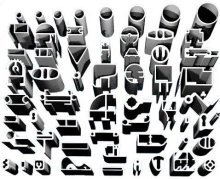

Трубы/Профили

7075 clad with 7072

AMS QQ-A-250/25 / AlZn5.5MgCu / 7075 clad with 7072 / T76

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.80 g/cm³ |

| Melting Point | 477 °C |

| Thermal Expansion | 23 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | %33 IACS |

| Mechanical Properties | Value |

| Proof Strength | 490 MPa |

| Yield Strength | 570 MPa |

| Shear Strength | 320 MPa |

| Elongation A50 mm | 12% |

| Hardness | 150 HB |

The Alclad aluminum alloy formed by cladding 7075 with 7072 provides a highly advantageous combination, adding a thin layer of corrosion-resistant 7072 to the high-strength 7075 core. This structure is especially favored in aerospace, defense, and high-performance automotive industries, where both structural durability and long-lasting surface protection are paramount. As a result, it offers an exceptional strength-to-weight ratio, fatigue resistance, and surface protection simultaneously.

This Alclad composition is suitable for anodizing, thereby enhancing both surface durability and aesthetics. While 7075 as a base alloy presents limited weldability, welding is possible under certain conditions with the use of appropriate filler metals and techniques. Despite its high hardness, the material can be bent to a certain degree when proper preheating and forming methods are applied, allowing for versatile geometric configurations and flexible manufacturing processes.

In high-vibration environments, the strength and fatigue resistance of the 7075 core, combined with the corrosion-resistant 7072 cladding, ensures that the alloy maintains its integrity over time, making it highly reliable for critical applications. In marine, humid, or salty conditions, the additional corrosion protection provided by the 7072 layer significantly extends the service life of components, ultimately reducing maintenance costs.

Advantages of this Alclad combination include exceptional strength, lightness, long-term corrosion resistance, suitability for anodizing, and stability under vibratory conditions. The drawbacks involve the need for careful machining due to its high strength, limited weldability, and the requirement of additional measures during forming processes. Nonetheless, 7075 Alclad with 7072 successfully meets the modern industry’s demand for an optimal balance of performance, durability, and corrosion protection.

ALLOY DESIGNATIONS

Sheet as; 7075 T76 Alclad 7072 ile, AMS QQ-A-250/25,

ASTM B209, DTD 5110

Choosing Factors for 7075 T76 clad with 7072:

- Strength: Good

- Machining: Normal

- Weldability: Poor

- Formability: Low

- Corrosion Resistance: Fair

- Heat Treating:Yes

TEMPER TYPES

AMS QQ-A-250/25 7075 is supplied in the following heat treatment types;

- T76

Aircraft structural elements

Friction and heat sensitive aerospace projects

Laboratory projects with high moisture content

- Sheet

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 3.17 up to & incl. 4.75 mm | 393 | 469 | %6 |

| Over 12.7 up to & incl. 25.4 mm | 414 | 490 | %6 |

Калькулятор Веса

Калькулятор Веса