قضبان مستديرة مرسومة على البارد

أنابيب الألمنيوم المسحوبة على البارد

2011

Cold Drawn/Finished (CF) / AlCu6BiPb (Soğuk Çekim) / 2011 / T3

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Copper (Cu) | 5,00 - 6,00 |

| Lead (Pb) | 0,20 - 0,60 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,30 |

| Nickel (Ni) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.83 g/cm³ |

| Melting Point | 540 °C |

| Thermal Expansion | 21.4 µm/m.°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | %39 IACS |

| Mechanical Properties | Value |

| Proof Strength | 290 MPa |

| Yield Strength | 379 MPa |

| Shear Strength | 221 MPa |

| Elongation A50 mm | 12% |

| Hardness | 95 HB |

5L36 - 1050A has excellent characteristic properties: Very good atmospheric corrosion resistance. Very good workability. High thermal and electrical conductivity (preferred alloy 1350). Attractive appearance, high reflectivity. Suitable for decorative anodising. Very good weldability with low mechanical properties.

ALLOY DESIGNATIONS

Aluminium alloy 5L36 - 1050A is covered by Standard BS EN 5L36 (1985)

TEMPER TYPES

The most common tempers for 5L36 - 1050A aluminium wire / rivet stock is as-drawn

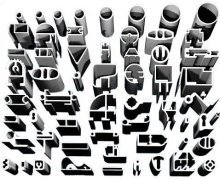

SUPPLIED FORMS

L36-1050A aluminium is supplied in Wire as rivet stock.

- Round Bar

- Wire

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 3,17 up to & incl. 38,1 | 260 MPa | 310 MPa | %10 |

| Over 38,13 up to & incl. 50,8 | 235 MPa | 295 MPa | %10 |

| Over 50,83 up to & incl. 82,5 | 205 MPa | 290 MPa | %14 |

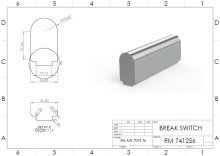

حساب الوزن

حساب الوزن