Rundstange Gezogen

Rundrohre Gezogen

2011

Cold Drawn/Finished (CF) / AlCu6BiPb (Soğuk Çekim) / 2011 / T3

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Copper (Cu) | 5,00 - 6,00 |

| Lead (Pb) | 0,20 - 0,60 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,30 |

| Nickel (Ni) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.83 g/cm³ |

| Melting Point | 540 °C |

| Thermal Expansion | 21.4 µm/m.°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | %39 IACS |

| Mechanical Properties | Value |

| Proof Strength | 290 MPa |

| Yield Strength | 379 MPa |

| Shear Strength | 221 MPa |

| Elongation A50 mm | 12% |

| Hardness | 95 HB |

Aluminium alloy 2011 is a high mechanical strength alloy that machines exceptionally well. Often called a Free Machining Alloy or ‘FMA’ it is well suited to use in automatic lathes.

ALLOY DESIGNATIONS

Aluminium alloy 2011, AMS QQ-A-225/3 is covered by Standard BS EN 2100 and has similarities to the following standard designations and specifications:

2011, ISO AlCu6BiPb, 3.1655

UNS A92011, BS FC1

TEMPER TYPES

The most common tempers for 2011 aluminium are:

- O - Soft

- T3 - Solution heat treated, cold worked and naturally aged

- T4 - Solution heat treated and naturaly aged to a substantially stable condition.

- T8 - Solution heat-treated, cold worked and then artificially aged.

- T451 - Solution heat-treated, stress-relieved by controlled stretching and then artificially overaged (between T73 and T76). The products receive no further straightening after stretching.

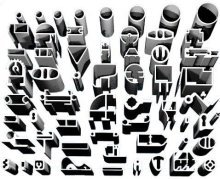

SUPPLIED FORMS

2011 aluminium is supplied in round bar.

- Round Bar

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 3,17 up to & incl. 38,1 | 260 MPa | 310 MPa | %10 |

| Over 38,13 up to & incl. 50,8 | 235 MPa | 295 MPa | %10 |

| Over 50,83 up to & incl. 82,5 | 205 MPa | 290 MPa | %14 |

Gewichts-Kalkulator

Gewichts-Kalkulator