2011

A-U5PbBi / AlCu6BiPb / 2011 / T4

| 化学性质 | % 值 |

| Silicon (Si) | 0,40 Max |

| Copper (Cu) | 5,00 - 6,00 |

| Lead (Pb) | 0,20 - 0,60 |

| Iron (Fe) | 0,70 Max |

| Zinc (Zn) | 0,00 - 0,30 |

| Aluminium (Al) | Balance |

| 物理特性 | 值 |

| Density | 2.82 g/cm³ |

| Melting Point | 540 °C |

| Thermal Expansion | 22,9 µm/m.°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | 39% IACS |

| 机械性能 | 值 |

| Proof Strength | 140 MPa |

| Yield Strength | 310 MPa |

| Shear Strength | 190 MPa |

| Elongation A50 mm | %18 |

| Hardness | 70 HB |

2011 T4 aluminum exhibits mid strength and is widely used in aerospace applications.

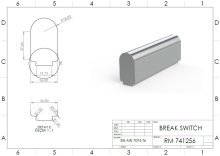

ALLOY DESIGNATIONS

2011 T4 has the following standard designations and specifications.

Extruded Round/Flat Bar and Tubes per; 2011 T4, ASTM B221, UNS A92011, WNR 3.1655, ISO AlCu6BiPb, AFNOR A-U5PbBi, UNE L-3192, UNI 9002/5

Choosing Factors for 2011 T4

- Strength: Moderate

- Machining: Excellent

- Weldability: Poor

- Formability: Good

- Corrosion Resistance: Weak

- Heat Treating: Yes

Some Well-Known Applications for 2011 T4

Precision machine parts,

Automotive trims,

Tube stems and fittings.

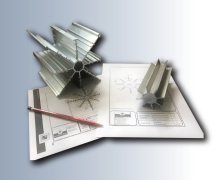

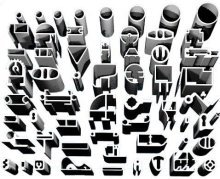

SUPPLIED FORMS

2011 T4 is produced/supplied in round/flat bar and tube/profile forms.

- Rod / Round Bar / Flat Bar

- Tube/Profile

交货:

| 机械性能 | |||

| 厚度 (mm) | 证明力量 (Min.) | 屈服强度 (Min.) | Uzama % |

| Up to & incl. 60 | 125 | 275 | %14 |

计算 重量计算

计算 重量计算