Barras Estiradas en Frío

Tubos Estirados en Frío

2011

Cold Drawn/Finished (CF) / AlCu6BiPb (Soğuk Çekim) / 2011 / T8

| Chemical Properties | % Value |

| Silicon (Si) | 0,40 Max |

| Copper (Cu) | 5,00 - 6,00 |

| Lead (Pb) | 0,20 - 0,60 |

| Iron (Fe) | 0,70 Max |

| Zinc (Zn) | 0,00 - 0,30 |

| Nickel (Ni) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.82 g/cm³ |

| Melting Point | 540 °C |

| Thermal Expansion | 22.9 µm/m°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 170 W/m.K |

| Electrical Resistivity | %46 IACS |

| Mechanical Properties | Value |

| Proof Strength | 310 MPa |

| Yield Strength | 420 MPa |

| Shear Strength | 240 MPa |

| Elongation A50 mm | 10% |

| Hardness | 100 HB |

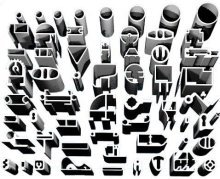

Aluminium alloy 2011 is a high mechanical strength alloy that machines exceptionally well. Often called a Free Machining Alloy or ‘FMA’ it is well suited to use in automatic lathes.

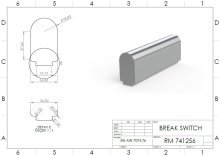

Cold Drawn Round/Flat Bars per; 2011 T8, ASTM B211, AMS QQ-A-225/3, UNS A92011, WNR 3.1655, ISO AlCu6BiPb, AFNOR A-U5PbBi, UNE L-3192, UNI 9002/5

Cold Drawn Tubes per; 2011 T8, ASTM B210, UNS A92011, WNR 3.1655, ISO AlCu6BiPb, AFNOR A-U5PbBi, UNE L-3192, UNI 9002/5

Choosing Factors for 2011 T8

- Strength: High

- Machining: Excellent

- Weldability: Weak

- Formability: Satisfactory

- Corrosion Resistance: Poor

- Heat Treating: Yes

Some Well-Known Applications for 2011 T8

In cigaratte holders,

In precise parts of clocks,

Also as a component of machined fittings.

- Rod / Round Bar / Flat Bar

- Tube/Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 3.17 up to & incl. 82.5 | 275 MPa | 310 MPa | %10 |

Calculador de Peso

Calculador de Peso