Platten

Blech

Rundstangen

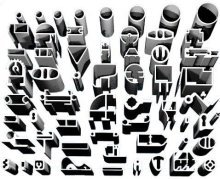

Rohre/ Extrusion/ Profil

2024

AMS QQ-A-225/6 / AlCu4Mg1 / 2024 / T8

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,50 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,30 - 0,90 |

| Magnesium (Mg) | 1,20 - 1,80 |

| Copper (Cu) | 3,80 - 4,90 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.78 g/cm³ |

| Melting Point | 502 °C |

| Thermal Expansion | 23 µm/m.°C |

| Modulus of Elasticity | 73.1 GPa |

| Thermal Conductivity | 121 W/m.K |

| Electrical Resistivity | 30% IACS |

| Mechanical Properties | Value |

| Proof Strength | 440 MPa |

| Yield Strength | 530 MPa |

| Shear Strength | 300 MPa |

| Elongation A50 mm | 5% |

| Hardness | 140 HB |

A medium to high strength alloy with, dependent upon temper, minimum Proof Stress up to 57 ksi / 390 Mpa and minimum Tensile Strength up to 66 ksi / 455 MPa

ALLOY DESIGNATIONS

Aluminium alloy 2024 T8 has similarities to the following standard designations and specifications:

As extruded round bar: AMS QQ-A-200/3, ASTM B221, DIN 3.1354

Choosing Factors for 2024 T8

- Strength: High

- Machining: Good

- Weldability: Average (Spot welding is the best choice)

- Formability: Poor

- Corrosion Resistance: Poor

- Heat Treating: Yes

Some Well-Known Applications for 2024 T8

Engine cowl skins,

In hydraulic valves,

It is also used in aircraft fittings.

SUPPLIED FORMS

Alloy 2024 T8 is supplied in round and flat bar forms.

- Round/Flat Bar

Gewichts-Kalkulator

Gewichts-Kalkulator