Листы/Плиты

Лист

Бар/Листовая Сталь

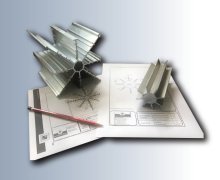

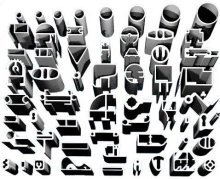

Трубы/Профили

2618A

ASTM B221 / AlCu2Mg1.5Ni / 2618A / T6

| Chemical Properties | % Value |

| Silicon (Si) | 0,10 - 0,25 |

| Manganese (Mn) | 0,00 - 0,25 |

| Magnesium (Mg) | 1,30 - 1,80 |

| Copper (Cu) | 1,90 - 2,70 |

| Titanium (Ti) | 0,04 - 0,10 |

| Iron (Fe) | 0,90 - 1,30 |

| Zinc (Zn) | 0,00 - 0,10 |

| Nickel (Ni) | 0,90 - 1,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.76 g/cm³ |

| Melting Point | 549 °C |

| Thermal Expansion | 21.6 µm/m°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 147 W/m.K |

| Electrical Resistivity | 37 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 350 MPa |

| Yield Strength | 420 MPa |

| Shear Strength | 260 MPa |

| Elongation A50 mm | %6 |

| Hardness | 120 HB |

Aluminium Alloy 2618A (Aluminum 2618) is a high strength aluminium alloy. Alloy 2618 (2618A) has good machinability and is fair resistance to atmospheric attack. Aluminium Alloy 2618A (Aluminum 2618) is typically used in aerospace and defence components. It is commonly used for pistons and rotating aircraft parts due to it's ability to work in higher temperature applications. 2618 is also used in high performance autosport applications

Extruded Round/Flat Bar, Forgings and Tubes per; 2618A T6, ASTM B221, UNS A92618, DTD 717, DTD 5084A, ISO AlCu2Mg1.5Ni, WNR 3.1924,

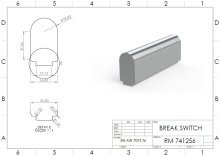

Choosing Factors for 2618A T6

- Strength: High

- Machining: Okay

- Weldability: Weak

- Formability: Okay

- Corrosion Resistance: Mediocre

- Heat Treating: Yes

Some Well-Known Applications for 2618A T6

In aircraft engines in the aerospace industry,

In autosports industry,

It has many areas of use, mainly in the defense industry.

- Round/Flat Bar

- Tube/Profile

Калькулятор Веса

Калькулятор Веса