Platos

Hojas

Barras Circulares

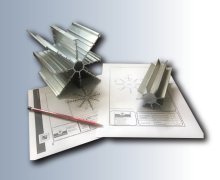

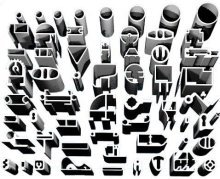

Tubos / Extrusion / Perfil

2618A

ASTM B211 / AlCu2Mg1.5Ni / 2618A / T6511

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,25 |

| Tin (Sn) | 0,00 - 0,05 |

| Manganese (Mn) | 0,00 - 0,20 |

| Magnesium (Mg) | 1,20 - 1,80 |

| Copper (Cu) | 1,80 - 2,70 |

| Lead (Pb) | 0,00 - 0,05 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,90 - 1,40 |

| Zinc (Zn) | 0,00 - 0,15 |

| Nickel (Ni) | 0,80 - 1,40 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.76 g/cm³ |

| Melting Point | 535 °C |

| Thermal Expansion | 21.6 µm/m°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 147 W/m.K |

| Electrical Resistivity | 36 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 372 MPa |

| Yield Strength | 441 MPa |

| Shear Strength | 262 MPa |

| Elongation A50 mm | 10% |

| Hardness | 115 HB |

Aluminium Alloy 2618A (Aluminum 2618) is a high strength aluminium alloy. Alloy 2618 (2618A) has good machinability and is fair resistance to atmospheric attack. Aluminium Alloy 2618A (Aluminum 2618) is typically used in aerospace and defence components. It is commonly used for pistons and rotating aircraft parts due to it's ability to work in higher temperature applications. 2618 is also used in high performance autosport applications.

As Extruded Round/Flat Bar and Tube; 2618A T6511, ASTM B221, UNS A92618, AIR 9048.150, ISO AlCu2Mg1.5Ni, WNR 3.1924, DTD 5014A

As Cold Drawn Round/Flat Bar and Tube; 2618A T6511, ASTM B211, UNS A92618, ISO AlCu2Mg1.5Ni, WNR 3.1924, EN 3553

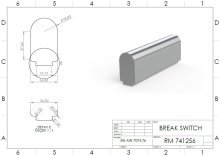

Choosing Factors for 2618A T6511

- Strength: High

- Machining: Okay

- Weldability: Bad

- Formability: Good

- Corrosion Resistance: Fair

- Heat Treating: Yes

Some Well-Known Applications for 2618A T6511

In the engines and fuselages of aircraft,

In response to the needs of the high-tech industry,

It has a wide range of applications, including car pistons and gears.

- Round/Flat Bar

- Tube/Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Up to & incl. 10 | Min 320 MPa | Min 400 MPa | %5 |

| Over 10 mm up to & incl. 100 mm | Min 340 MPa | Min 420 MPa | 5% |

Calculador de Peso

Calculador de Peso