板/板

钣金

棒条/金属板

管道/型材

5052

AMS 4016 / AlMg2.5 / 5052 / H32

| 化学性质 | % 值 |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,05 - 0,25 |

| Manganese (Mn) | 0,40 - 1,00 |

| Magnesium (Mg) | 2,20 - 2,80 |

| Copper (Cu) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| 物理特性 | 值 |

| Density | 2.68 g/cm³ |

| Melting Point | 607 °C |

| Thermal Expansion | 22.1 µm/m-°C |

| Modulus of Elasticity | 68 GPa |

| Thermal Conductivity | 138 W/m.K |

| Electrical Resistivity | 35 % IACS |

| 机械性能 | 值 |

| Proof Strength | 180 MPa |

| Yield Strength | 230 MPa |

| Shear Strength | 140 MPa |

| Elongation A50 mm | 15% |

| Hardness | 60 HB |

The 5052 H32 aluminum alloy is known for its excellent machinability, high corrosion resistance, and moderate strength. Belonging to the aluminum-magnesium alloy class, it is commonly used in industries such as maritime, automotive, construction, and aerospace. The H32 temper provides medium hardness and durability to the alloy through a heat treatment process, ensuring that it remains flexible while maintaining its strength. Its lightweight and good machinability make it ideal for components that require shaping and use in harsh environmental conditions.

ALLOY DESIGNATIONS

5052 H32 has the following standard designations and specifications.

Sheets and plates per; 5052 H32, AMS 4016, AMS QQ-A-250/8, ISO AlMg2.5, WNR 3.3523, UNS A95052, ASTM B209

Cold Drawn Round/Flat Bar and Wires per; 5052 H32, ASTM B211, ISO AlMg2.5, WNR 3.3523, UNS A95052, AMS QQ-A-225/7

Choosing Factors for 5052 H32

- Strength: Medium

- Machining: Good

- Weldability: High

- Formability: Satisfactory

- Corrosion Resistance: Perfect

- Heat Treating: None

Some Well-Known Applications for 5052 H32

In applications where light-weight and corrosion resistance are needed,

In fuel hose circuits of aircraft,

There are also many application areas in the transportation sector.

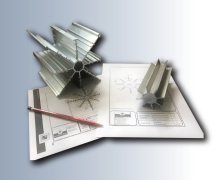

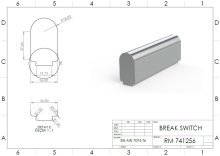

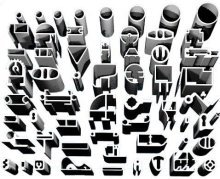

SUPPLIED FORMS

5052 H32 is produced/supplied in plate, sheet round/flat bar and tube/profile forms.

- Tube/Profile

- Plate

- Sheet

- Round/Flat Bar

交货:

计算 重量计算

计算 重量计算