Barras Estiradas en Frío

Tubos Estirados en Frío

2024

Cold Drawn/Finished (CF) / AlCu4Mg1 (Soğuk Çekim) / 2024 / T3510

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,5 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,30 - 0,90 |

| Magnesium (Mg) | 1,20 - 1,80 |

| Copper (Cu) | 3,80 - 4,90 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.78 g/cm³ |

| Melting Point | 502 °C |

| Thermal Expansion | 23 µm/m.°C |

| Modulus of Elasticity | 73.1 GPa |

| Thermal Conductivity | 121 W/m.K |

| Electrical Resistivity | 30% IACS |

| Mechanical Properties | Value |

| Proof Strength | 320 MPa |

| Yield Strength | 460 MPa |

| Shear Strength | 270 MPa |

| Elongation A50 mm | 9% |

| Hardness | 120 HB |

The cold-drawn 2024 T3510 aluminum alloy is known for its high strength and good machinability. Belonging to the aluminum-copper alloy class, this material is commonly used in applications where lightweight and durability are critical. It is widely preferred in demanding engineering fields such as aerospace, automotive, and space industries. The cold-drawing process results in a homogeneous microstructure, which enhances the alloy's mechanical properties and makes it easier to machine.

The 2024 T3510 alloy has limited suitability for anodizing. Its high copper content can hinder the formation of the desired protective oxide layer during anodizing. Therefore, alternative coating methods are typically used to provide protection. In terms of weldability, the 2024 T3510 alloy requires careful handling due to its high copper content. The risk of cracking during welding is increased, so special welding techniques must be employed. However, with the right approach, strong and durable welds can be achieved.

Regarding formability, the 2024 T3510 alloy offers excellent machinability. Despite its high strength, bending and shaping operations can be successfully carried out due to the benefits of the cold-drawing process. This makes the alloy easy to work with in a variety of applications. The 2024 T3510 alloy is also suitable for use in high-vibration environments. Its durability and resistance to vibrations make it an ideal choice for automotive and aerospace applications, particularly in components like engine parts and chassis, ensuring long-lasting performance.

In terms of corrosion resistance, the 2024 T3510 alloy shows limited resistance due to its high copper content. This can restrict its use in marine or humid environments. However, these limitations can be overcome with appropriate coatings and surface treatments to enhance its corrosion resistance. The 2024 T3510 aluminum alloy offers advantages such as high strength, good machinability, and lightweight properties, but it also has drawbacks, including welding challenges and limited corrosion resistance.

ALLOY DESIGNATIONS

Aluminium alloy 2024 has similarities to the following standard designations and specifications:

Extrusion round bars per: 2024 T3510, AMS QQ-A-200/3, AMS 4164, EN 2633, ASTM B221

Choosing Factors for 2024 T3510

- Strength: Good

- Machining: Okay

- Weldability: Medium (Spot welding is the best choice)

- Formability: Low

- Corrosion Resistance: Poor

- Heat Treating: Yes

Some Well-Known Applications for 2024 T3510

In wing stringers,

As components of hydraulic valves,

It is also used as components of computers.

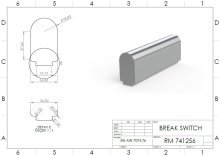

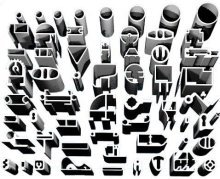

SUPPLIED FORMS

Alloy 2024 T3510 is supplied in round and flat bar forms.

- Round / Flat Bar

Calculador de Peso

Calculador de Peso