Листы/Плиты

Лист

Бар/Листовая Сталь

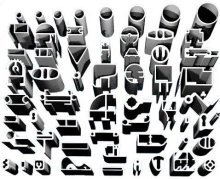

Трубы/Профили

7075

AMS 4166 / AlZn5.5MgCu / 7075 / T73

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.81 g/cm³ |

| Melting Point | 477°C |

| Thermal Expansion | 23.4 µm/m.°C |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 155 W/m.K |

| Electrical Resistivity | 33% IACS |

| Mechanical Properties | Value |

| Proof Strength | 435 MPa |

| Yield Strength | 505 MPa |

| Shear Strength | 290 MPa |

| Elongation A50 mm | 13% |

| Hardness | 130 HB |

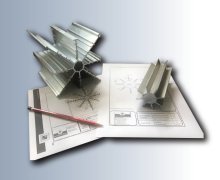

7075 T6 is an high strength alloy which also exhibits low stress corrosion cracking resistance, therefore it eventually generated the need of improving the corrosion resistance of 7075 alloy. Thus the 7075 T73 heat treatment - tempering has been developed. While the T73 and especially the T7351 heat treatment - tempering provide very high corrosion resistance, they also provide processing properties with almost perfect precision tolerances without surface distortion in 7075 aluminum. Therefore, it is used a lot in the aviation industry and since the beginning of the 2000s most old machinery / mold companies, especially in the US and Europe, have shifted to start using them as well. Since 2007, Referans Metal has been the pioneering company by producing and supplying 7075 T73 in plate and bar forms for the machine / mold industry in Türkiye for the first time ever. Evaluation of the technical data in such applications by our engineering department serves great importance in drawing and design processes.

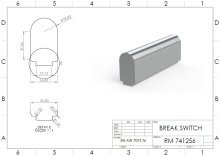

Sheet and Plate as; 7075 T73, AMS QQ-A-250/12,

ASTM B209

Extrusion Seamless Pipe, Profile as; 7075 T73, AMS QQ-A-200/11,

AMS 4166, ASTM B241

Choosing Factors for 7075 T73:

- Strength: Fair

- Machining: Average

- Weldability: Weak

- Formability: Low

- Corrosion Resistance: Good

- Heat Treating: Yes

TEMPER TYPES

AMS-W-700/7 7075 is supplied in the following heat treatment types:

- O

- T6

- T73

- T76

Some Well-Known Applications for 7075 T73:

Sports equipment

Gear equipment

In the production of fixed articulated carrier apparatus

- Plate

- Sheet

- Tube / Profile / Extrusions

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| over 6.35 up to & incl. 50.8 | 389 MPa | 472 MPa | 6.0 - 7.0 |

| over 50.8 up to & incl. 63.5 | 355 MPa | 451 MPa | 6 |

| over 63.5 up to & incl. 76.2 | 334 MPa | 437 MPa | 6 |

Калькулятор Веса

Калькулятор Веса