Platten

Blech

Rundstangen

Rohre/ Extrusion/ Profil

7150

AMS 4307 / AlZn6CuMgZr(A) / 7150 / T61511

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,15 |

| Chromium (Cr) | 0,10 - 0,22 |

| Manganese (Mn) | 0,00 - 0,20 |

| Magnesium (Mg) | 2,00 - 2,90 |

| Copper (Cu) | 1,2 - 1,90 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,20 |

| Zinc (Zn) | 7,20 - 8,20 |

| Aluminium (Al) | Balance |

| Titanium + Zirconium (Ti+Zr) | 0,08 - 0,15 |

| Physical Properties | Value |

| Density | 2,86 g/cm³ |

| Thermal Expansion | 24.7 µm/m.°C |

| Modulus of Elasticity | 69,1 GPa |

| Mechanical Properties | Value |

| Proof Strength | min. 537 MPa |

| Yield Strength | min. 580 MPa |

| Shear Strength | min. 490 MPa |

| Elongation A50 mm | 11% |

| Hardness | 160 HB |

7050 T61511 aluminum exhibits mid strength and is widely used in aerospace applications.

ALLOY DESIGNATIONS

7150 T61511 has the following standard designations and specifications.

Extruded Round/Flat Bar and Tubes per; 7150 T61511, AMS 4307, UNS A97150, ISO AlZn6CuMgZr, ASTM B221

Choosing Factors for 7150 T61511

- Strength: High

- Machining: Good

- Weldability: Medium

- Formability: Weak

- Corrosion Resistance: Very good

- Heat Treating: Yes

Some Well-Known Applications for 7150 T61511

As a component of airplane seat rails,

In the structure of engines,

Also used in keels.

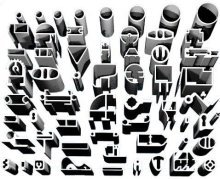

SUPPLIED FORMS

7150 T61511 is produced/supplied in round/flat bar and tube/profile form.

- Round/Flat Bar

- Tube/Profile

DELIVERY:

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| 25,4 mm | 565 MPa | 607 MPa | %11 |

Gewichts-Kalkulator

Gewichts-Kalkulator