6061

AMS 4128 / AlMg1SiCu / 6061 / T451

| Chemical Properties | % Value |

| Silicon (Si) | 0,40 - 0,80 |

| Chromium (Cr) | 0,04 - 0,35 |

| Manganese (Mn) | 0,00 - 0,15 |

| Magnesium (Mg) | 0,80 - 1,20 |

| Copper (Cu) | 0,15 - 0,40 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,70 g/cm³ |

| Melting Point | 582 °C |

| Thermal Expansion | 23.4 µm/m.°C |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 170 W/m.K |

| Electrical Resistivity | 43% IACS |

| Mechanical Properties | Value |

| Proof Strength | 131 MPa |

| Yield Strength | 228 MPa |

| Shear Strength | 152 MPa |

| Elongation A50 mm | %20 |

| Hardness | 63 HB |

6061 T451 aluminum exhibits mid strength and is widely used in aerospace applications.

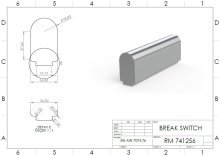

ALLOY DESIGNATIONS

6061 T451 has the following standard designations and specifications.

As Plate/Sheet; 6061 T451, AMS QQ-A-250/11, AMS 4022F, UNS A96061, WNR 3.3211, ISO AlMg1SiCu, ASTM B209

As Cold Drawn Round/Flat Bar and Tube; 6061 T451, AMS 4128, UNS A96061, WNR 3.3211, ISO AlMg1SiCu, ASTM B211

Choosing Factors for 6061 T451

- Strength: Mediocre

- Machining: Okay

- Weldability: Very good

- Formability: Okay

- Corrosion Resistance: Excellent

- Heat Treating: Yes

Some Well-Known Applications for 6061 T451

It is used in the machinery industry as machine parts and equipment,

In structures requiring high strength,

In electric poles and helicopter materials.

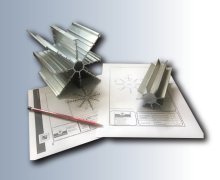

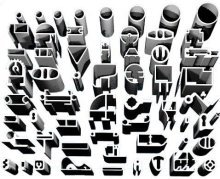

SUPPLIED FORMS

6061 T451 is produced/supplied in plate/sheet round/flat bar and tube/profile forms.

- Rod / Round Bar / Flat Bar

- Plate

- Sheet

- Tube/Profile

DELIVERY:

Calculador de Peso

Calculador de Peso