Rundstange Gezogen

Rundrohre Gezogen

6082

Cold Drawn/Finished (CF) / AlSi1MgMn (Soğuk Çekim) / 6082 / T5

| Chemical Properties | % Value |

| Silicon (Si) | 0,70 - 1,30 |

| Chromium (Cr) | 0,00 - 0,25 |

| Manganese (Mn) | 0,40 - 1,00 |

| Magnesium (Mg) | 0,60 - 1,20 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 555 °C |

| Thermal Expansion | 24 x 10^-6 /K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 160 W/m.K |

| Electrical Resistivity | 42% IACS |

| Mechanical Properties | Value |

| Proof Strength | 260 MPa |

| Yield Strength | 300 MPa |

| Shear Strength | 180 MPa |

| Elongation A50 mm | 9.0 % |

| Hardness | 80 HB |

Cold-drawn 6082 T5 aluminum alloy is widely recognized for its impressive strength-to-weight ratio, excellent machinability, and moderate formability, which make it suitable for a range of demanding applications. This alloy is frequently used in the construction, automotive, aerospace, and marine industries where durability and reliable performance are essential. In structural applications such as load-bearing components, frameworks, and supports, 6082 T5 provides the robust strength necessary to maintain integrity under stress.

A notable feature of the 6082 T5 alloy is its compatibility with anodizing processes, allowing for an improved surface finish and enhanced corrosion protection. This anodizing compatibility is a valuable asset for outdoor and architectural applications, as it both protects the material from environmental damage and enhances its appearance.

In terms of weldability, 6082 T5 performs well, especially with MIG and TIG welding, making it adaptable for manufacturing designs that require complex assemblies. However, care must be taken in welding, as the thermal conductivity of the material can influence weld quality if not managed correctly.

This alloy also offers decent formability, particularly in cold-drawn formats, though it’s not as easy to bend or form as softer alloys. Nonetheless, with the right techniques, it can be shaped into components like automotive parts, beams, and braces without significant loss of structural integrity. Additionally, 6082 T5 performs reliably in environments with high vibration, making it well-suited for applications involving dynamic stress, such as parts in transportation and machinery.

When it comes to corrosion resistance, the 6082 T5 alloy offers robust protection, especially against environmental factors like moisture and saline conditions. This makes it highly desirable in marine and coastal settings, where materials are regularly exposed to corrosive elements.

Among the strengths of 6082 T5 are its excellent machinability, corrosion resistance, and strength in high-vibration settings. However, it has some drawbacks: its formability is limited compared to more pliable aluminum alloys, and excessive exposure to high temperatures may affect its mechanical properties. Despite these limitations, 6082 T5 remains a favored material in industries that require both structural strength and durability.

Cold Drawn Tubes per; 6082 T5, ISO AlSi1MgMn, ASTM B210, UNS A96082, WNR 3.2315

Cold Drawn Round/Flar Bar, Tubes per; 6082 T5, ISO AlSi1MgMn, ASTM B211, UNS A96082, WNR 3.2315, BS L 114, BS HT 30

Choosing Factors for 6082 T5

- Strength: Very good

- Machining: Fair

- Weldability: Good

- Formability: Okay

- Corrosion Resistance: Excellent

- Heat Treating: Yes

Some Well-Known Applications for 6082 T5

As a component of sea boats and boats,

In train wagons and bicycle frames,

It has many different uses, including also nuclear technology.

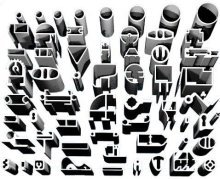

- Rod / Round Bar / Flat Bar

- Tube/Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| 6 - 12,5 | 410 MPa | 460 MPa | |

| 12,5 - 25 | 410 MPa | 460 MPa | |

| 25 - 40 | 400 MPa | 450 MPa | |

| 40 - 63 | 390 MPa | 430 MPa | |

| 63 - 90 | 390 MPa | 430 MPa | |

| 90 - 115 | 370 MPa | 420 MPa | |

| 115 - 140 | 350 MPa | 410 MPa | |

Gewichts-Kalkulator

Gewichts-Kalkulator