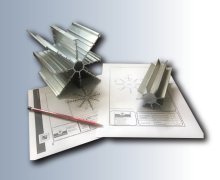

Platos

Hojas

Barras Circulares

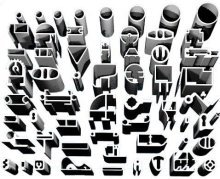

Tubos / Extrusion / Perfil

5086

AMS QQ-A-250/7 / AlMg4 / 5086 / H111

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,05 - 0,25 |

| Magnesium (Mg) | 3,50 - 4,50 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,15 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Manganese (Mn) | 0,20 - 0,70 |

| Physical Properties | Value |

| Density | 2,66 g/cm³ |

| Melting Point | 585 °C |

| Thermal Expansion | 23.8 µm/m.°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | 31% IACS |

| Mechanical Properties | Value |

| Proof Strength | 120 MPa |

| Yield Strength | 269 MPa |

| Shear Strength | 170 MPa |

| Elongation A50 mm | %20 |

| Hardness | 70 HB |

The 5086 H111 aluminum alloy is known for its excellent corrosion resistance, good machinability, and moderate strength. As part of the aluminum-magnesium alloy class, it is commonly used in industries such as maritime, automotive, construction, and other applications exposed to harsh environmental conditions. The H111 temper provides the alloy with medium hardness, ensuring it remains flexible while offering durability. This feature allows the alloy to be used in demanding environments while maintaining its lightweight and durable characteristics.

The 5086 H111 aluminum alloy is highly suitable for anodizing. Anodizing creates a protective oxide layer on the alloy’s surface, enhancing corrosion resistance and providing an aesthetically pleasing finish. This makes it especially advantageous in outdoor applications and the maritime industry. In terms of weldability, the 5086 H111 alloy performs well. As an aluminum-magnesium alloy, it can be welded using proper techniques to create strong, reliable welds.

In terms of bending and forming, the 5086 H111 aluminum alloy is very flexible and machinable. Despite being cold-worked, it can be easily shaped and bent with the right processing techniques, making it suitable for the production of complex shapes in industries such as automotive, construction, and maritime. Additionally, the 5086 H111 alloy is suitable for use in high-vibration environments. Its high durability and elastic modulus make it ideal for components like engine parts, transport equipment, and other vibration-exposed components.

Regarding corrosion resistance, the 5086 H111 aluminum alloy shows exceptional durability, particularly against seawater and humid conditions. This makes the 5086 H111 alloy an ideal material for maritime applications and equipment exposed to moisture. The advantages of the 5086 H111 alloy include high corrosion resistance, good machinability, and lightweight properties, while its disadvantages include limited performance under high temperatures and certain strength applications.

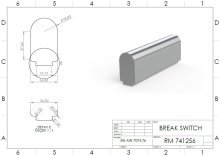

As Plate/Sheet; 5086 H111, AMS QQ-A-250/7, ASTM B209, ISO AlMg4, DIN AlMg4Mn UNS A95086, ASTM B632, ASTM B928, AMS QQ-A-250/19, WNR 3.3545

As Extrusion Rod, Flat Bar, Wire; 5086 H111, ASTM B221, UNS A95086, ASTM B928, WNR 3.3545, AMS QQ-A-200/5

As Cold Drawn Rod,Flat Bar,Wire; 5086 H111, ASTM B211, UNS A95086, ASTM B928, ASTM B210, WNR 3.3545

As Extruded Seamless Tube: 5086 H111, WWW-T-700/5, ISO AlMg4, DIN AlMg4Mn UNS A95086, ASTM B241, WNR 3.3545

Choosing Factors for 5086 H111

- Strength: Very good

- Machining: Good

- Weldability: Good

- Formability: Good

- Corrosion Resistance: Great

- Heat Treating: Yes

Some Well-Known Applications for 5086 H111

It is used in ship bridges, boat and yacht hulls,

As marine materials component,

In cryogenic applications,

TV towers, armor plating and tank parts in the defense industry.

- Plate

- Sheet

- Rod / Round Bar / Flat Bar

- Tube/Profile

Calculador de Peso

Calculador de Peso