板/板

钣金

棒条/金属板

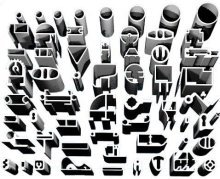

管道/型材

2017

AMS 4110 / AlCu4MgSi / 2017 / T4

| 化学性质 | % 值 |

| Silicon (Si) | 0,20 - 0,80 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,40 - 1,00 |

| Magnesium (Mg) | 0,40 - 1,00 |

| Copper (Cu) | 3,50 - 4,50 |

| Titanium (Ti) | 0,00 - 0,25 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| 物理特性 | 值 |

| Density | 2.79 g/cm³ |

| Melting Point | 510 °C |

| Thermal Expansion | 22.9 µm/m.°C |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 140 W/m.K |

| Electrical Resistivity | 37 % IACS |

| 机械性能 | 值 |

| Proof Strength | 276 MPa |

| Yield Strength | 427 MPa |

| Shear Strength | 262 MPa |

| Elongation A50 mm | 18% |

| Hardness | 105 HB |

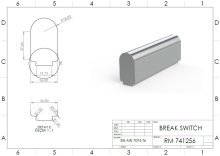

As Sheet/Plate; 2017 T4, ASTM B209, ISO AlCu4MgSi, UNS A92017, WNR 3.1325, DIN AlCuMg1

As Cold Drawn Round/Flat Bar, Profile, Wire; 2017 T4, AMS QQ-A-225/5, ASTM B211, UNS A92017, AMS 4118 (Superseded the AMS 4110), WNR 3.1325, DIN AlCuMg1, ASTM B316, ASTM B565

As Extruded Round/Flat Bar, Profile, Wire; 2017 T4, AMS QQ-A-200/2, ASTM B221, UNS A92017, WNR 3.1325, DIN AlCuMg1

Choosing Factors for 2017 T4

- Strength: Very good

- Machining: Excellent

- Weldability: Moderate

- Formability: Good

- Corrosion Resistance: Average

- Heat Treating: Yes

Some Well-Known Applications for 2017 T4

On rivets, clothes hangers,

As aircraft material in the aerospace industry,

It is also used in the transportation sector, as well as in military equipment and vehicles.

- Plate/Sheet

- Rod / Round Bar / Flat Bar

- Tube/Profile

| 机械性能 | |||

| 厚度 (mm) | 证明力量 (Min.) | 屈服强度 (Min.) | Uzama % |

| Over 25 up to & incl. 75 | 270 MPa | 400 MPa | %10 |

| Over 75 up to & incl. 150 | 260 MPa | 390 MPa | %9 |

| Over 150 up to & incl. 200 | 240 MPa | 370 MPa | %8 |

| Over 200 up to & incl. 250 | 220 MPa | 360 MPa | %7 |

计算 重量计算

计算 重量计算