Barres Étirées à Froid

Tubes Étirés à Froid

2124

Cold Drawn/Finished (CF) / AlCu4Mg1 (Soğuk Çekim) / 2124 / T6

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,20 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,30 - 0,90 |

| Magnesium (Mg) | 1,20 - 1,80 |

| Copper (Cu) | 3,80 - 4,90 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,30 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.78 g/cm³ |

| Melting Point | 502 °C |

| Thermal Expansion | 21.9 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 145 W/m.K |

| Electrical Resistivity | 38 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 430 MPa |

| Yield Strength | 490 MPa |

| Shear Strength | 280 MPa |

| Elongation A50 mm | 6 % |

| Hardness | 110 HB |

The cold-drawn 2124 T6 aluminum alloy is known for its high strength and excellent fatigue resistance. It is widely used in aerospace and aviation industries for structural components, in automotive parts requiring durability, and in heavy industrial equipment. This alloy is suitable for anodizing, which enhances surface hardness and wear resistance, thus extending its lifespan and adding an aesthetic finish. Due to its copper content, its corrosion resistance is moderate, so additional protective coatings are recommended for outdoor and humid environments.

Weldability is limited, so it is typically assembled using mechanical fastening methods such as bolting or riveting. Cold drawing improves its formability, making it adaptable to complex shapes and suitable for bending applications. Additionally, it performs reliably in high-vibration environments, making it ideal for moving parts and applications where fatigue resistance is crucial. The 2124 T6 alloy’s advantages include high strength, anodizing compatibility, and good machinability, while its drawbacks are limited weldability and moderate corrosion resistance. These qualities make it a reliable choice for projects where durability and strength are paramount.

ALLOY DESIGNATIONS

Aluminium alloy 2024 T6 has similarities to the following standard designations and specifications:

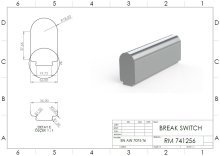

Cold Drawn Round Bars per: 2124 T6, ASTM B211, AMS 4339, UNS A92124

Cold Drawn Tubes per: 2124 T6 AMS 4087, WW-T-700/3, ASTM B211, UNS A92124

Choosing Factors for 2124 T6

- Strength: High

- Machining: Good

- Weldability: Moderate (Spot welding is the best choice)

- Formability: Weak

- Corrosion Resistance: Low

- Heat Treating: Yes

Some Well-Known Applications for 2124 T6

In military vehicles,

In project based aerospace applications.

It is also used in fields where transverse ductility is required.

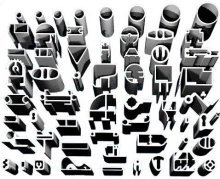

SUPPLIED FORMS

2124 T6 is supplied in round/flat bar and tube/ profile forms.

- Flat/round bar

- Tube/profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 38.1 up to & incl. 50.8 | 393 MPa | 455 MPa | %5 |

| Over 50,8 up to & incl. 76,2 | 393 MPa | 448 MPa | %4 |

| Over 76,2 up to & incl. 101,6 | 386 MPa | 448 MPa | %4 |

| Over 101,6 up to & incl. 127 | 379 MPa | 441 MPa | %4 |

| Over 127 up to & incl. 152,4 | 372 MPa | 434 MPa | %4 |

Calculateur de Poids

Calculateur de Poids