5182

EN AW / AlMg4.5Mn0.4 / 5182 / H18

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,50 |

| Chromium (Cr) | 0,00 - 0,25 |

| Manganese (Mn) | 0,20 - 0,50 |

| Magnesium (Mg) | 4,00 - 5,00 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,35 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.65 g/cm³ |

| Melting Point | 577 °C |

| Thermal Expansion | 23.8 x 10^-6 /K |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 126 W/m.K |

| Electrical Resistivity | 28% IACS |

| Mechanical Properties | Value |

| Proof Strength | 320 MPa |

| Yield Strength | 390 MPa |

| Shear Strength | 220 MPa |

| Elongation A50 mm | 2% |

| Hardness | 112 HB |

5182 exhibits mid strength and is widely used in aerospace/marine applications.

ALLOY DESIGNATIONS

5182 H18 has the following standard designations and specifications.

Sheets and plates per; 5182 H18, ISO AlMg4.5Mn0.4, DIN AlMg5Mn, WNR 3.3549, UNS A95182, ASTM B209

Choosing Factors for 5182 H18

- Strength: Mediocre

- Machining: Very good

- Weldability: Good

- Formability: Good

- Corrosion Resistance: Satisfactory

- Heat Treating: None

Some Well-Known Applications for 5182 H18

As a component of packaging equipment and machines,

Automobile chassis and panels in the automotive industry,

It is also used in medical equipments.

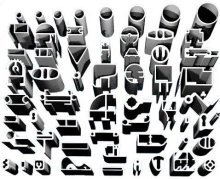

SUPPLIED FORMS

5182 H18 is produced/supplied in the sheet form.

- Sheet

- Plate

DELIVERY:

Калькулятор Веса

Калькулятор Веса