Platos

Hojas

Barras Circulares

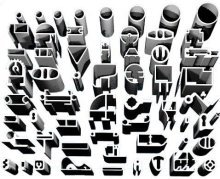

Tubos / Extrusion / Perfil

2011

ASTM B211 / AlCu6BiPb / 2011 / T6

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Copper (Cu) | 5,00 - 6,00 |

| Lead (Pb) | 0,20 - 0,60 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,30 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.83 g/cm³ |

| Melting Point | 540 °C |

| Thermal Expansion | 22.9 µm/m°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | %39 IACS |

| Mechanical Properties | Value |

| Proof Strength | 290 MPa |

| Yield Strength | 395 MPa |

| Shear Strength | 220 MPa |

| Elongation A50 mm | 17% |

| Hardness | 97 HB |

2011 T6 aluminum alloy is renowned for its excellent machinability, high strength, and moderate corrosion resistance. Enhanced with copper content, this alloy is ideal for applications requiring precision machining. The T6 temper indicates that the alloy has undergone solution heat treatment and artificial aging to achieve maximum strength, making it suitable for demanding mechanical loads.

This alloy is widely used in automotive, aerospace, and precision machine parts. Its capability for high-speed machining provides significant advantages in producing intricate and detailed components. However, 2011 T6 has limited compatibility with anodizing; its copper content requires specialized processing during anodizing. In terms of weldability, the alloy has constraints, with mechanical fasteners or specialized welding techniques often being preferred.

Regarding bending and forming, 2011 T6 aluminum alloy offers limited formability due to its high strength. There is a risk of cracking in complex forming processes, although proper techniques can achieve the desired results. Its fatigue resistance and mechanical stability make it highly reliable in high-vibration environments and under dynamic loads.

The corrosion resistance of this alloy is moderate, and surface protection treatments are recommended for outdoor or corrosive conditions. Advantages of 2011 T6 include exceptional machinability, high mechanical strength, and fatigue resistance, while disadvantages include limited weldability, low formability, and moderate corrosion resistance. These characteristics make 2011 T6 aluminum alloy an excellent choice for projects requiring precision machining and high strength.

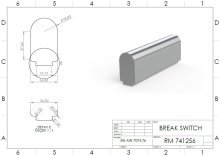

Extruded Round/Flat Bars and Tubes per; 2011 T6, ASTM B221, UNS A92011, WNR 3.1655, ISO AlCu6BiPb, AFNOR A-U5PbBi, UNE L-3192, UNI 9002/5

Cold Drawn Round/Flat Bars per; 2011 T6, AMS QQ-A-225/3, ASTM B211, UNS A92011, WNR 3.1655, ISO AlCu6BiPb, AFNOR A-U5PbBi, UNE L-3192, UNI 9002/5

Cold Drawn Tubes per; 2011 T6, ASTM B210, UNS A92011, WNR 3.1655, ISO AlCu6BiPb, AFNOR A-U5PbBi, UNE L-3192, UNI 9002/5

Choosing Factors for 2011 T6

- Strength: High

- Machining: Perfect

- Weldability: Poor

- Formability: Average

- Corrosion Resistance: Poor

- Heat Treating: Yes

Some Well-Known Applications for 2011 T6

In decorative elements,

Atomizer parts,

Also in precise machine parts.

- Rod / Round Bar / Flat Bar

- Tube/Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 3,17 up to & incl. 38,1 | 260 MPa | 310 MPa | %10 |

| Over 38,13 up to & incl. 50,8 | 235 MPa | 295 MPa | %10 |

| Over 50,83 up to & incl. 82,5 | 205 MPa | 290 MPa | %14 |

Calculador de Peso

Calculador de Peso